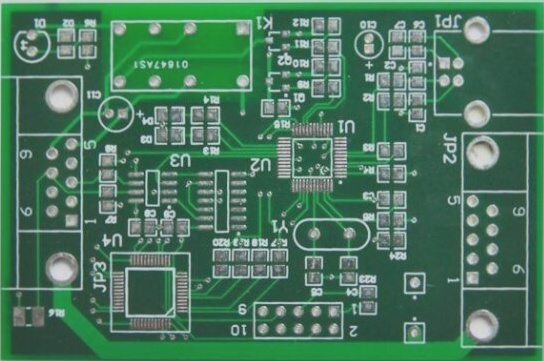

PCB Proofing Process Overview

PCB proofing, also known as PCB prototype production, is a crucial step in the manufacturing of printed circuit boards. It involves testing the design and functionality of the PCB before mass production. The process typically includes the following steps:

1. Contacting the Manufacturer

- Provide necessary documents, process requirements, and quantities to the manufacturer.

- Receive a quote, place orders, and track production progress.

2. Cutting

- Objective: Cut large sheets into smaller pieces to meet engineering data and customer specifications.

- Process: Cut board according to requirements, grind, and finish.

3. Drilling

- Objective: Drill apertures at specified positions based on engineering data.

- Process: Stack boards, drill, inspect, and repair if needed.

4. Sink Copper

- Objective: Deposit a thin layer of copper on insulating hole walls.

- Process: Rough grinding, copper sinking, chemical treatment.

5. Graphics Transfer

Transfer images from production film to the board.

- Process: Printing, drying, developing, and inspecting.

6. Graphic Plating

- Objective: Deposit required copper and gold-nickel/tin layers.

- Process: Degreasing, etching, plating, and washing.

7. Film Removal

- Objective: Remove anti-plating coating film to expose copper layers.

- Process: Soaking, rinsing, and scrubbing.

8. Etching

Use chemical reaction to corrode non-circuit copper areas.

9. Green Oil Application

- Objective: Transfer green oil film to protect the circuit during soldering.

- Process: Printing, curing, and exposing.

10. Character Printing

- Objective: Provide identification marks.

- Process: Printing characters for easy identification.

11. Gold-Plated Fingers

- Objective: Plate nickel/gold for hardness and wear resistance.

- Process: Degreasing, plating, and washing.

12. Tin Plating

- Objective: Coat exposed copper surfaces for corrosion protection.

- Process: Coating, leveling, and drying.