We have come a long in digitalization, and there is still a lot more to come. However, taking a look at today’s world, AI has taken over almost everything, and it is making things predictive and efficient by any means. Almost everything today has Artificial intelligence, which works with Artificial Intelligence PCBA.

However, it is not the digital world that Artificial Intelligence is enhancing and transforming. It has also helped transform the brains behind all digital devices. We are talking about the Artificial intelligence PCBA and components. From the manufacturing process to making the components and their usage better, Artificial intelligence has helped everything.

Here we will be elaborating on how the artificial intelligence PCBA world is evolving swiftly and how artificial intelligence is helping a lot in it.

How artificial intelligence PCBA is transforming the PCB world in different aspects.

PBC manufacturing and PBC assembly are two very different aspects of the PCB world. Artificial intelligence is helping both the manufacturing and assembly aspects in different ways. Here is an insight into how artificial intelligence PCBA is evolving and how the PCB manufacturing world is also transforming:

1- More AI-enabled devices mean fewer human requirement

The first thing you will see is that more artificial intelligence-enabled devices are used and made these days. These are the devices that enhance productivity and efficiency by different means. It calls for fewer human requirements and more device requirements.

As more and more processes and things adapt to these technologies, the need for such devices increases. Simultaneously, the need for artificial intelligence-enabled PCBs increases. The increasing need for PBC manufacturing and artificial intelligence PCBA means more progress in the PCB world. In this way, artificial intelligence is transforming the PCB world

2- Efficient devices require efficient circuits behind them

The best way to understand this is by taking an example of your mobile phone from a few years ago. Such devices only had basic features with not much stuff to do. We pressed a button, and the phone functioned accordingly. However, the phones we have today have all the latest features. The interesting fact is that most of those features are artificial intelligence-based.

Whether it be facial recognition or suggestion, artificial intelligence is always there. So, this need calls for better and more efficient circuits. That is why PCB manufacturers develop better chips and circuit boards with every iteration of a phone model. This is how artificial intelligence increases the need for a better circuit to transform the PCB world.

3- Artificial intelligence helps in designing better circuits.

Artificial intelligence has to do a lot with our software advancements, and these advancements help transform the PCB world. One of the best ways artificial intelligence helps the PCB industry is that we can design better circuits.

A few years ago, humans were designing all aspects of the circuits. So, there was a performance bottleneck that was keeping us from achieving perfection. Now artificial intelligence is used for most of the design work. Although humans have a huge role in specifying the design, artificial intelligence makes the design of every circuit better.

In this way, we can pack more features into circuits because of better design. Similarly, it has become possible to pack more circuit estate in devices of the same size because of better circuit design.

4- AI integrated PCB manufacturing requires less time manufacturing.

PCB manufacturing and assembly is a long process. The most time-consuming parts of this process include placing small components and applying the soldering paste. As circuits become smaller, this becomes difficult for humans to achieve super-fast and accurate PCB manufacturing and assembly results.

However, artificial intelligence PCBA and PCB manufacturing are the processes where AI integrated machines work for everything. Here mechanical arms are trained using artificial intelligence and machine learning to apply solder paste accurately. Similarly, they place the components accurately. This altogether helps in achieving less manufacturing time for PCB making and assembly

5- AI integrated PCB manufacturing is cheaper in terms of workforce

Consider that you have 10 men working for you in your PCB manufacturing and assembly unit. Paying them wages will cost way more than investing in a machine because it will be a one-time investment. There is a lot of handwork in the PCB manufacturing and assembly process that we can automate with artificial intelligence-enabled machines.

This is how things become cheaper. These days most PCB manufacturing and assembly units are automated. Those machines need no more than one or two operators for everything. In this way, the costs can be cut. This results in cheaper PCBs meaning that everyone can access them. The subsequent result is the increase in PCB demand that transforms the PCB world.

6- AI integrated PCB manufacturing makes efficient use of the raw materials.

If you know about the PCB manufacturing process, you will know how much raw material is wasted. It is only because of the bottleneck of human interference. We usually cannot achieve as precise results as a machine can achieve. This can be in all fields like:

- Designing

- Cutting

- Printing

- Etching and more

So, when artificial intelligence integrated machines take over, they ensure that every bit of raw material is utilized in the best way. The use of automatic design printing software tools has high importance here.

7- AI integrated PCB manufacturing offers better quality assurance.

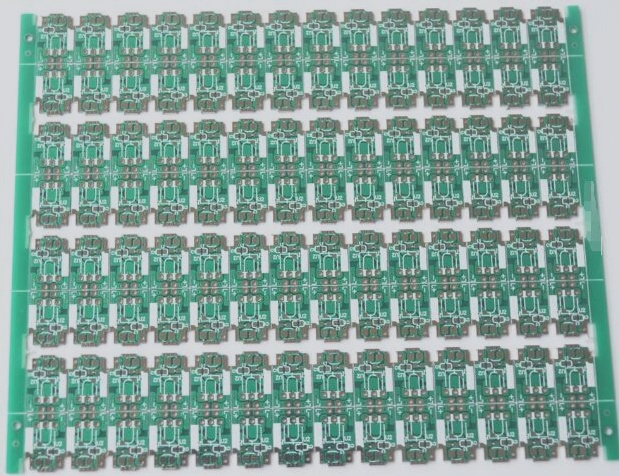

Quality assurance matters a lot in the PCB world. It is because most PCBs are not made in units or tens. They are made in the hundreds or thousands. So, if we cannot provide quality assurance, then we may not be able to achieve the best results in manufacturing and assembly.

However, the machines backed with artificial intelligence technology provide higher accuracy with lower tolerance. It means that every PCB manufacturing unit can ensure better quality assurance and better quality.

8- AI integrated PCB manufacturing makes fewer chances of errors.

Reducing errors and increasing accuracy is what humans have always been striving for. However, things are very different now that artificial intelligence does a major part in PCB making and assembly. These days optical inspection units and circuit testing units ensure no errors in the circuit whatsoever. With no errors, the efficiency of the PCB manufacturing world has enhanced a lot.

9- AI integrated PCB manufacturing enables shrinking the size of PCBs.

With artificial intelligence, we can shrink the design of PCBs. Usually, this is done by dividing circuits into different parts and sometimes combining different parts of the circuit. Using the same hardware for different functions also helps make the size of circuits small. On top of everything, artificial intelligence-enabled software for designing circuits plays a major role in shrinking the size of PCBs.

10- AI integrated PCB manufacturing is making this process a green process

The integration of artificial intelligence in PCB making and assembly makes everything green(environment friendly) in different ways. Two of them are:

Better PCBs last longer, reducing the need for newer ones

So, the first one is that better quality PCBs last longer. An amazing example is the mobile phones that last longer now. With better quality PCBs in them, the mobile phones can perform amazingly well for around 5 years, making us not need to upgrade to a new device. Another amazing example is that different mobile manufacturers take older devices back to recycle parts. It makes the whole PCB making and assembly process greener and better for the environment.

Efficient production means less waste.

The second factor is that artificial intelligence-enabled devices ensure that the production is efficient by all of the following means:

- Less material wastage

- Less energy wastage

So, all in all, artificial intelligence helps us make better PCBs that can easily last longer, helping the environment.

11- The shrinking size of devices calls for smaller circuits.

In the olden days, devices were bigger. However, we have been able to achieve smaller sizes with smaller circuits. This works like a chain reaction, and only because of artificial intelligence PCBA and PCB manufacturing are we now able to consistently decrease the size of devices.

The circuits that were a few inches a few years back are now only centimeters, with processors going in nanometers. This advancement is currently on, and we can expect artificial intelligence to bring revolutionary changes in the PCB world in the coming years.

Verdict

Although humans started things, now most things are under the supervision and control of artificial intelligence PCBA. The interesting fact is that it is not bad for humans because, on every level, it is making things better and more efficient. Here we covered a few factors about how artificial intelligence has transformed and is transforming the PCB world.

We can imagine the transformation by comparing the size of mobile phones a few years ago and today. Nobody knows how efficient things will become with the help of artificial intelligence in the PCB world. Therefore, it is essential for us to understand the latest AI technology. For now, it is artificial intelligence PCBA that is making things better in every aspect of life.