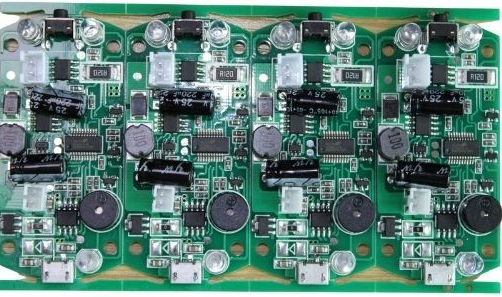

Under typical circumstances, people often inquire about how long it takes to process the latest price of PCBA. This should begin with an understanding of the various links involved in PCBA production and manufacturing. Many are aware that PCBA is a general term for PCB assembly in China. It comprises three main components: (1) PCB circuit boards, (2) SMT assembly, and (3) electronic component soldering. Thus, the latest price of PCBA must be determined by these three elements.

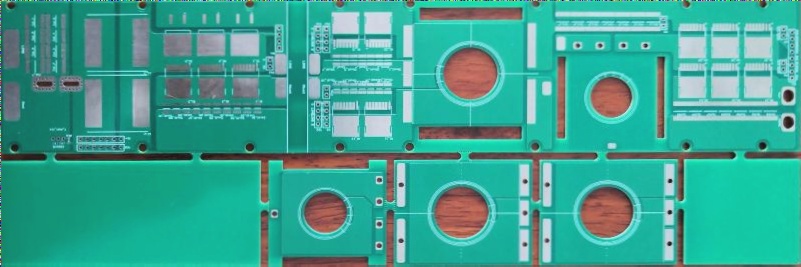

1. **PCB Board:** The materials and documentation required for the PCB board are crucial for determining its latest price. If all materials are complete, compiling them allows for an accurate quote. Special processes incur additional charges, along with other miscellaneous expenses. A PCB factory can provide a comprehensive price quote within the last two hours. However, if there are numerous outstanding price requests, the timeline may differ.

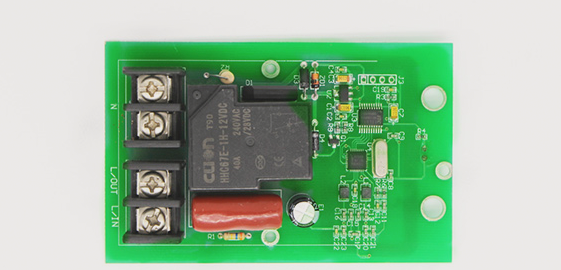

2. **SMT Assembly Section:** This module primarily involves calculating processing fees. Typically, PCBA factories base their costs on the number of pins. Some charge per pin, while others charge per foot. This can be a significant factor. Each component usually has at least two pins. If pricing is based on a single pin, the cost per pin may exceed that of the per-foot pricing, which complicates the evaluation.

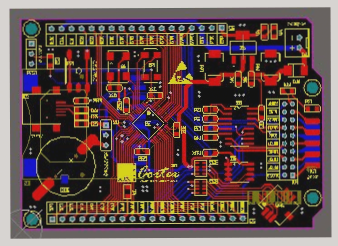

Third, the electrical PCBA sub-component module: electronic components include standard RC parts and specialized components. The current market for standard components is quite transparent, making price evaluation simpler. However, certain specialized BGA/IC components can pose challenges. For instance, during the tumultuous Huawei incident last year, many specialized electronic components were affected by international embargoes, stringent approval processes, lengthy customs clearance, and fluctuating prices. Consequently, the latest pricing cycle typically spans 3 to 4 days.

Cleaning printed circuit boards (PCBs) for high-performance products is a delicate task, much like the manufacturing of the circuit boards themselves. Using incorrect cleaning methods can lead to damaged connections, loose components, and compromised materials on the PCB. To prevent these issues, it is crucial to exercise the same level of care when selecting cleaning methods as you did during the design, specification, and production phases of the circuit boards.

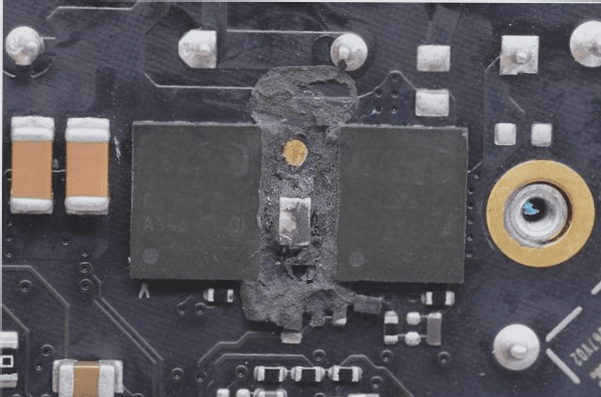

Various contaminants can accumulate on the PCB. Employing the right corresponding methods to address these problems is essential for effective cleaning and can alleviate potential headaches. One common issue is dust buildup in or around the PCB. Gentle, small brushes (such as horsehair paintbrushes) can effectively remove dust without harming the components. Even the tiniest brushes can access hard-to-reach areas, such as beneath components. While compressed air can clean many regions of the chip factory, it may inadvertently damage critical connections, so caution is advised when using it.

High-temperature operations can transform certain wax-coated components into magnets for dust and dirt, resulting in sticky residues that cannot be easily removed with a brush or vacuum. In other instances, thick residues from spilled soda can create a mess on the board. Regardless of the source, these issues should be addressed before accumulation affects performance. Most dirt can be effectively cleaned using agents such as isopropyl alcohol (IPA) with a Q-tip, small brush, or clean cotton cloth. It is best to clean the PCB in a well-ventilated area, ideally using a fume hood for solvent-based cleaning with IPA.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me