What is a PCB (Printed Circuit Board)?

A PCB is a circuit board that has been coated with a conductive material. It is used in electronic devices such as computers, cell phones, and other electronic gadgets. It can also be used to make an electric guitar, which is why it is also called a pickguard.

The process of making PCBs starts by creating a stencil from the desired shape. Then, the board is coated with copper or nickel, and then the paint will be used to cover the board. This process can take up to 10 hours for just one board.

The cost of mounting printed circuit boards

The cost of installation is calculated using the calculator. You can also send us an order for evaluation by mail, attaching all the necessary files. The final cost depends on the terms, complexity and volume of the order. Please note that after checking the information you provided in the application, the manager-technologist can adjust the cost and / or terms.

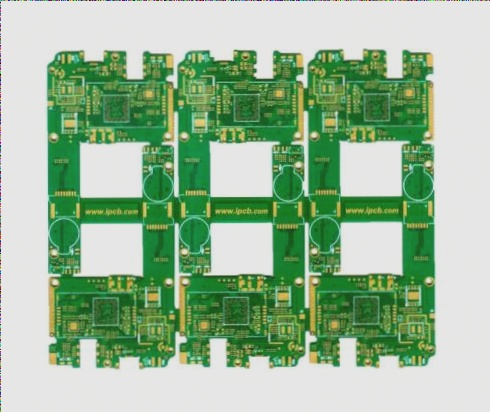

Serial assembly of printed circuit boards imposes a number of requirements on the printed circuit board, components and documentation. First of all, the boards must be in multi-blanks, the exceptions may be rectangular boards with minimum overall dimensions of 60mm on each side.

If the boards have a smaller linear size, it is necessary to make a multi-blank. The multi-blank must have technological fields with fiducial marks. It is not allowed to supply boards and blanks with significant warping. The complete set for surface mounting is accepted only in the original packaging (pallets, cases, coils).

Pay attention to the date of manufacture of the components, the low price of components is often associated with long-term storage. Such components may have oxidized terminals and lead to massive solder failure. Documentation must match PCB and CAD files. In case of disagreement, we will contact you immediately, but in an emergency, we prioritize the CAD file, then the assembly drawing, then the specification and the PCB.

In case of detection of significant problems and inconsistencies (which make it difficult to carry out the planned radio installation), as well as the provision of substandard tolling raw materials, the production manager can agree on a new cost for mounting printed circuit boards or postpone the time or even the date of delivery of the order to work until the issue is resolved.

Why a PCB Assembly is Used?

A PCB Assembly is a specialized form of mechanical assembly that is used to attach electrical components to a PCB (Printed Circuit Board). A PCB Assembly has many advantages over other types of manufacturing. It is more cost-effective than traditional methods and faster than manual assembly.

The first advantage is that it uses less material which helps with the cost and speed.

The second advantage is that it helps reduce the number of people needed for manufacturing. The third advantage is that it ensures quality in the end product as there are fewer chances for errors to occur during production.

Benefits of Using a PCB

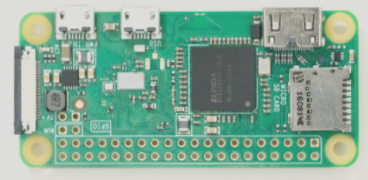

Printed circuit boards are used in many applications such as robotics, avionics, and defense systems. They can be made of a variety of materials and have a wide range of uses.

The benefits of using printed circuit boards include:

- High reliability: Printed circuits are more durable than other types of circuits.

- Versatility: Printed circuit boards can be assembled into high-performance devices of various sizes, shapes, and configurations.

- Low cost: Printed circuit boards are less expensive than other types of circuits.

How a Printed Circuit Board Assembly (PCBA) is Made?

PCBA is a process that involves assembling and soldering together the components of a circuit board using solder paste. The paste is applied to the copper-clad laminate (CCL) on the circuit board and then heated to melt it, forming a liquid layer of solder between the components. Then, by applying heat and pressure, the components are soldered together.

First, a stencil is created with the desired layout of all the traces on the PCB. This stencil defines where all of the components will go. Next, a masking tape is applied to protect areas that are not being worked on. Then, stencils with different layers are created for each component to make sure they fit properly onto their respective layers. Finally, these stencils are placed onto an assembly. PCBA is made this way:

- The PCB design is created using CAD software.

- The design is sent to a PCB manufacturer for manufacturing.

- The PCBs are then delivered to the assembly house where they are assembled into a final product with all other parts required for the final product.

PCBs are typically made of copper or fiberglass. The PCB is then etched with chemicals that dissolve the copper and form patterns on the board. These patterns are called tracks and connect different components of the circuit board.

PCB assembly includes many steps to create a finished product, including drilling holes for connectors, soldering wires to components, and placing components onto the board. It’s done in this order because it’s easiest to drill holes before soldering wires onto components and so on.

The Cost of a PCB Assembly

PCBA costs can vary depending on the complexity of the product and the number of components that are used. The cost may also be affected by country, region, and the quality of materials used for fabrication. Labor costs include wages for workers who assemble devices as well as materials such as solder paste, soldering irons, and fluxes. Material costs include PCBs; solder paste, solders, and fluxes.

The most expensive type of PCB assembly is through SMT (Surface Mount Technology), which is a method where components are soldered onto a circuit board instead of having wires connected to it. With this type, there are more steps involved before it can be completed, so it will take more time to complete and will cost more money than other types.

A simple PCB with just a few components can be made for as low as $0.15 per square inch while complex PCBs with over 100 parts can cost up to $3 per square inch. The prices also vary depending on whether you’re buying from China or not. A general rule of thumb is that a simple PCB assembly would cost around $1,000 to $2,000.

The Average Cost of a Printed Circuit Board Assembly (PCBA)

The average cost of a Printed Circuit Board Assembly (PCBA) is $1,890.50. The final cost depends on how much time the painter spends on each step in the process as well as what type of materials they use. The most expensive part is the copper and the least expensive is the soldering iron.

The manufacturing cost of a Printed Circuit Board Assembly (PCBA) is also an important factor in determining the total cost of manufacturing products. This figure can be affected by the number of parts, labor, overhead costs, and materials used in its production.

Traditionally, PCB assembly is a highly manual process that has been conducted by skilled workers who use a wide variety of tools and techniques. This process requires skillful hands with a detailed understanding of the PCB design and its components. But with new technologies such as 3D printing and laser cutting, PCB assembly has become more automated so it can be done by machines or even robots instead of humans.

The main reason for the high cost of a PCBA is due to the labor-intensive nature of the process. There are several steps in making a PCBA, and each step requires different skillsets and tools. For example, many different types of solder paste require different equipment and processes to make them.

PCBA prices vary from country to country. They depend on the market demand and the quality of the raw material. For example, in China, PCBA prices are relatively lower compared to other countries because of cheaper labor costs. In Vietnam, on the other hand, PCBA prices are high due to high labor costs and less availability of raw materials.

Conclusion

The technology of PCB assembly has been around for decades. The first PCBs were printed with a stencil and then etched in a vacuum chamber. This process was expensive, and it took hours to complete one board.

PCBA has an important role in the electronics industry and it’s one of the most important parts of electronics assembly. It’s used for mixed-signal integrated circuits with millions of transistors and capacitors on a single chip. This makes it difficult for traditional manufacturers to produce due to the high demand for this product

PCBA is now more accessible due to the advent of 3D printing, which allows for quicker production time and lowers costs. However, the quality of PCBs made with 3D printing methods is not as good as those made by traditional methods.

PCB assembly is an integral part of product manufacturing that involves assembling electronic components on a circuit board using solder paste or wire braid to attach them. It is also used in electronics repair to replace faulty components on circuit boards that are no longer functional or useable.