Factors Affecting PCB Copy Board Cost

- Circuit Board Size

- Number of Circuit Board Layers

- Device Density

- Difficulty of Operation

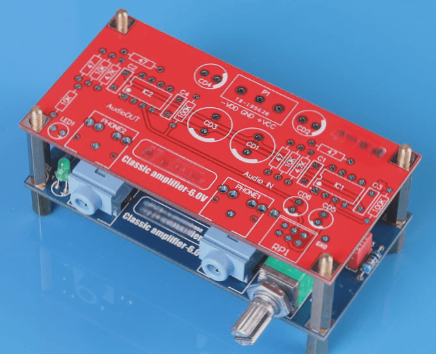

The size of the PCB plays a crucial role in determining the cost. Larger boards require more polishing time, increasing the risk of damage and thus raising the copying cost.

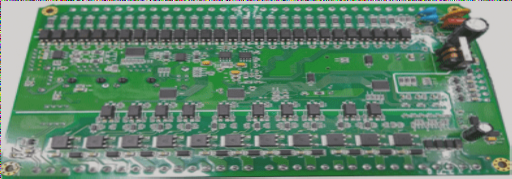

The complexity of the copying process increases with more layers and various buried and blind holes, leading to higher costs for boards with multiple layers.

The density of components impacts the workload and complexity of copying. Boards with high component density require meticulous attention, resulting in higher copying costs.

The complexity of operating a circuit board copying process depends on factors like board integrity, thickness, line width, and hole types, influencing the overall cost.

Factors Influencing Copy Board Cost

- PCB Board Size

- PCB Layers

- PCB Solder Joints

- Copy Board Project

Larger boards require more polishing time, increasing the risk of damage and raising the copying cost.

More layers and complex structures slow down the copying speed and add to the difficulty, resulting in increased copying costs.

Higher device density with more solder joints leads to increased workload and higher copying costs.

The number of files required and additional services like chip decryption impact the overall copying cost. Different document requirements may affect the final price.

Quoting for PCB Copying

Many companies offer circuit board copying along with material procurement and processing services. Customers may benefit from discounts if they choose the same company for the entire process, potentially reducing the copying price or receiving free services.

The cost of PCB copying varies significantly and involves more than just cloning the board. Additional services like BOM list creation, chip decryption, prototyping, or mass production may also contribute to the overall cost.

I trust this information addresses your inquiries!

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย