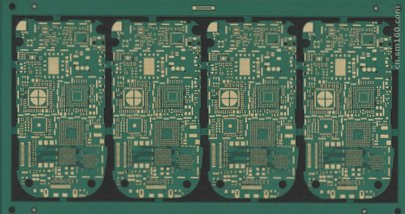

PCB copy board is often referred to as PCB imitation or PCB cloning in the industry. Simply put, it involves replicating the same or similar PCB board used in electronic products. The entire process of copying a PCB board requires a certain level of technical expertise and a precise operational method. Let me provide a detailed explanation.

PCB copy board is essentially a form of reverse engineering of a PCB design. The first step involves removing components from the printed circuit board to create a Bill of Materials (BOM) list. The empty board is then scanned to create an image, which is further used to generate a PCB board drawing file using copying software. This file is then sent to a PCB factory for production of the board (PCBA). Following this, components are added by procuring the necessary parts based on the BOM list. The end result is an exact replica of the original printed circuit board.

Copy board, also known as board modification, involves conducting reverse technology research on a designed PCB board. After reviewing extensive information, the process of copying the board can be summarized as follows:

1. Begin by obtaining a piece of PCB and documenting the model, parameters, and positions of all essential components on paper. Pay close attention to details such as the diode orientation, transistor placement, and IC gap direction. It is recommended to take photos of the crucial parts using a digital camera, as some components may be difficult to identify on modern printed circuit boards.

2. Next, remove all components and clean the PCB with alcohol to remove tin from the PAD holes. Place the PCB in a scanner and adjust the scanned pixel settings to capture a clearer image. Lightly polish the top and bottom layers with water gauze paper until the copper film shines, then scan both layers separately in color using Photoshop. Ensure the PCB is positioned correctly in the scanner to obtain usable images.

3. Adjust the canvas contrast and brightness to enhance the contrast between areas with copper film and those without. Convert the second image to black and white and check the clarity of the lines. If necessary, repeat this step until the lines are clear. Save the images as black and white BMP format files (e.g., TOP.BMP and BOT.BMP) and use Photoshop to correct any graphic issues.

4. Convert the BMP files into PROTEL format files and overlay the two layers in PROTEL. Verify the alignment of PADs and VIAs on both layers to confirm the accuracy of the previous steps. If any discrepancies are found, repeat the third step. Precision is crucial in PCB copying to ensure quality and accuracy.

5. Convert the TOP layer BMP file to TOP.PCB and focus on converting the SILK layer accurately. Trace the lines on the TOP layer and place components according to the second step’s drawing. Remove the SILK layer after completing the drawing and repeat the process for all layers.

6. Import the TOP.PCB and BOT.PCB files into PROTEL and merge them into a single image.

7. Print the TOP LAYER and BOTTOM LAYER onto transparent film using a laser printer (1:1 ratio) and overlay the film onto the PCB. Thoroughly inspect for errors in the final step to ensure accuracy and completion.

For multilayer boards, carefully polish the inner layers and repeat the copying process from the third to the fifth step. Naming conventions for graphics may vary based on the number of layers, with double-sided copying typically simpler than multi-sided boards. Extra caution is necessary for multi-sided board copy boards to prevent misalignment issues, particularly with internal vias and non-vias.

PCB copy board is essentially a form of reverse engineering of a PCB design. The first step involves removing components from the printed circuit board to create a Bill of Materials (BOM) list. The empty board is then scanned to create an image, which is further used to generate a PCB board drawing file using copying software. This file is then sent to a PCB factory for production of the board (PCBA). Following this, components are added by procuring the necessary parts based on the BOM list. The end result is an exact replica of the original printed circuit board.

Copy board, also known as board modification, involves conducting reverse technology research on a designed PCB board. After reviewing extensive information, the process of copying the board can be summarized as follows:

1. Begin by obtaining a piece of PCB and documenting the model, parameters, and positions of all essential components on paper. Pay close attention to details such as the diode orientation, transistor placement, and IC gap direction. It is recommended to take photos of the crucial parts using a digital camera, as some components may be difficult to identify on modern printed circuit boards.

2. Next, remove all components and clean the PCB with alcohol to remove tin from the PAD holes. Place the PCB in a scanner and adjust the scanned pixel settings to capture a clearer image. Lightly polish the top and bottom layers with water gauze paper until the copper film shines, then scan both layers separately in color using Photoshop. Ensure the PCB is positioned correctly in the scanner to obtain usable images.

3. Adjust the canvas contrast and brightness to enhance the contrast between areas with copper film and those without. Convert the second image to black and white and check the clarity of the lines. If necessary, repeat this step until the lines are clear. Save the images as black and white BMP format files (e.g., TOP.BMP and BOT.BMP) and use Photoshop to correct any graphic issues.

4. Convert the BMP files into PROTEL format files and overlay the two layers in PROTEL. Verify the alignment of PADs and VIAs on both layers to confirm the accuracy of the previous steps. If any discrepancies are found, repeat the third step. Precision is crucial in PCB copying to ensure quality and accuracy.

5. Convert the TOP layer BMP file to TOP.PCB and focus on converting the SILK layer accurately. Trace the lines on the TOP layer and place components according to the second step’s drawing. Remove the SILK layer after completing the drawing and repeat the process for all layers.

6. Import the TOP.PCB and BOT.PCB files into PROTEL and merge them into a single image.

7. Print the TOP LAYER and BOTTOM LAYER onto transparent film using a laser printer (1:1 ratio) and overlay the film onto the PCB. Thoroughly inspect for errors in the final step to ensure accuracy and completion.

For multilayer boards, carefully polish the inner layers and repeat the copying process from the third to the fifth step. Naming conventions for graphics may vary based on the number of layers, with double-sided copying typically simpler than multi-sided boards. Extra caution is necessary for multi-sided board copy boards to prevent misalignment issues, particularly with internal vias and non-vias.