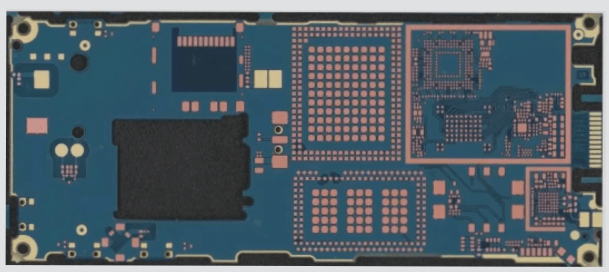

The Importance of Component Layout in High-Quality PCB Designs

When creating PCB designs, it is crucial to not only meet performance standards but also consider the arrangement of components for functionality, durability, and visual appeal. A well-thought-out component layout is essential for a successful design, covering aspects such as installation, mechanical stress, thermal considerations, signal integrity, and aesthetics.

1. Installation

Installation guidelines ensure the smooth integration of the circuit board into the chassis or enclosure without any issues. Proper positioning of connectors is vital for specific application scenarios.

2. Mechanical Stress

The PCB must withstand external forces and vibrations. Strategic placement of holes and connectors, along with proper board shape, is necessary. Attention should be given to the bending strength of custom-shaped holes for long-term reliability.

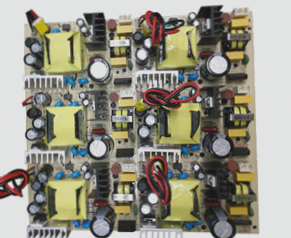

3. Thermal Considerations

Effective heat dissipation and positioning are critical, especially for high-power devices. Thermal isolation measures between circuits are essential to prevent adverse temperature effects.

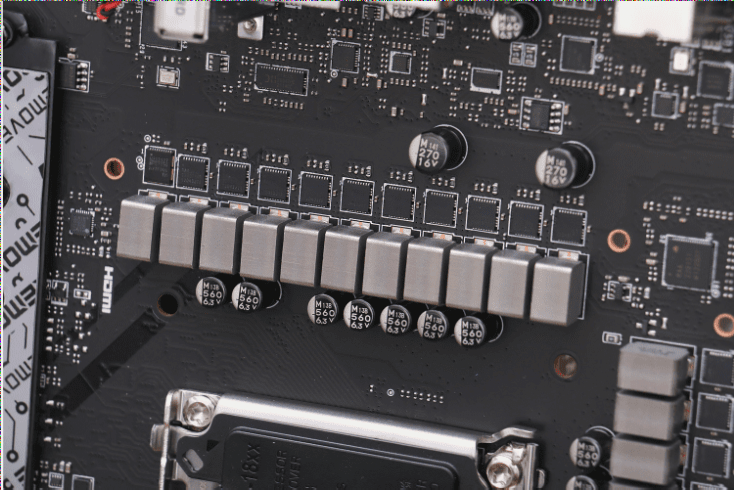

4. Signal Integrity

Signal interference must be minimized by separating signal circuits, managing AC/DC components, and designing ground layouts effectively. Attention to signal trace orientation and proper shielding is crucial for optimal performance.

5. Aesthetics

In PCB design, the visual appeal of component arrangement and trace routing is essential. While functionality is key, aesthetic quality becomes crucial in high-performance scenarios, especially for double-sided boards that are not easily visible.

If you require PCB manufacturing services, feel free to contact us.