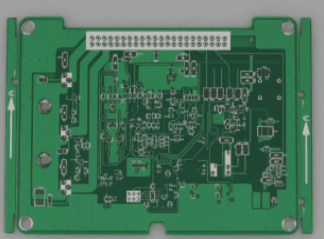

Key Considerations for Automotive PCB Manufacturing

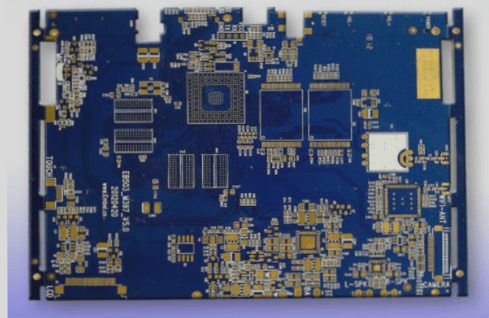

Automotive PCBs are vital components in today’s automotive systems, requiring high reliability and adherence to strict safety standards. Manufacturers face challenges in meeting the unique demands of this sector, necessitating a comprehensive understanding of the market.

1. Importance of Reliability and Quality Control

Manufacturers must prioritize reliability and low defect rates to meet industry standards. Compliance with TS16949 and achieving low DPPM are critical indicators of success. Without a robust quality control process, companies risk facing significant setbacks.

2. Specialized Testing Practices

- The “Second Test” Method: Some manufacturers employ a secondary testing phase post high-voltage breakdown to detect latent defects, ensuring only reliable PCBs enter the market.

- Bad Board Foolproof Test System: Implementing innovative systems like Good Board Marking and Bad Board Error Prevention enhances testing accuracy and reduces human errors.

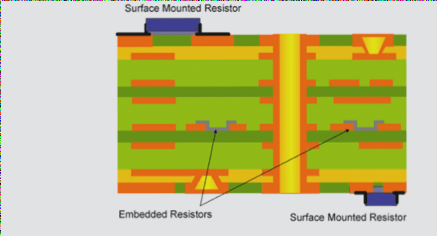

3. PPM Quality System Implementation

Adopting a Parts Per Million (PPM) quality system enables real-time defect tracking and reduction. Statistical Process Control (SPC) methods and microsectioning aid in identifying and resolving production issues efficiently.

4. Comparative Testing for Performance Evaluation

Comparing PCB performance across different batches and suppliers through Comparative Testing helps in selecting the most reliable testing systems for critical applications like automotive PCBs.

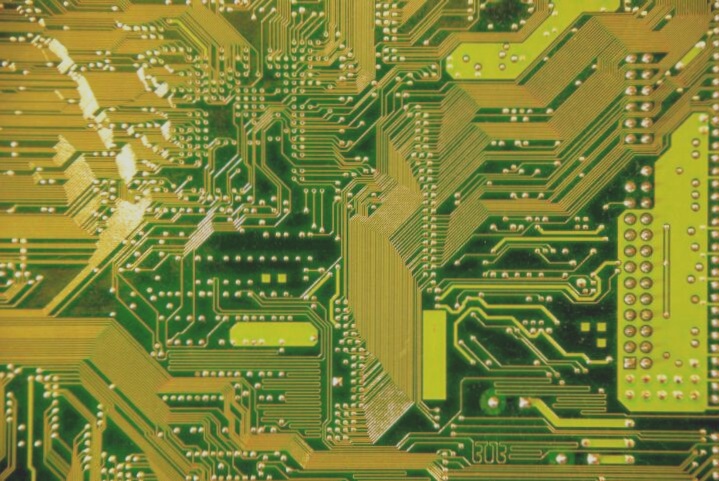

Optimizing Test Parameters

Improving PCB testing involves increasing the test parameters used in the process. By utilizing higher voltage and tighter thresholds, manufacturers can identify more defects, especially those that may be missed at lower test settings.

- A leading Taiwanese PCB manufacturer in Suzhou implements test parameters like 300V, 30MΩ, and 20Ω for testing automotive PCBs. These elevated test parameters aid in detecting subtle defects that might otherwise go unnoticed, ensuring that only top-quality boards pass the test.

Periodic Verification of Test Equipment

Ensuring the accuracy of testing machines over time is essential as prolonged use can lead to degradation, causing internal resistance and other test parameters to drift. Therefore, it is vital to regularly verify and calibrate testing equipment to uphold precision and consistency.

- Many prominent PCB companies adhere to a schedule of routine maintenance and recalibration of their test equipment, typically every six months to a year. This practice helps maintain the accuracy and reliability of testing parameters.

- Regular maintenance also contributes to the extended performance and stability of test systems, diminishing the chances of defects slipping through due to equipment malfunctions.

Conclusion: Continuous Pursuit of Zero Defects

Striving for “zero defects” in automotive PCBs remains a primary objective for manufacturers, despite the challenges posed by equipment limitations, processes, and raw materials. Even the top 100 PCB manufacturers globally are continuously seeking new approaches to decrease PPM rates and enhance product quality. The ongoing integration of advanced testing systems and data-centric quality control techniques will be instrumental in minimizing defects and attaining elevated standards in PCB manufacturing.