Optimizing PCB Trace Width for Temperature Control and Current Management

When designing a PCB board, it’s crucial to consider the trace width to ensure efficient heat dissipation and proper current flow. Here are some key points to keep in mind:

1. Importance of Trace Width

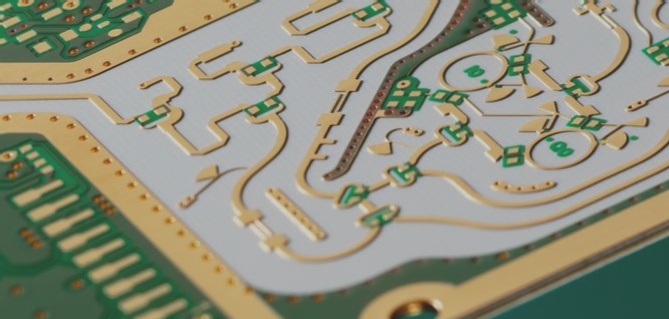

- Copper, a strong conductor on PCB boards, requires appropriate sizing to manage temperature rise.

- Trace width affects the current carrying capacity and temperature control of the board.

2. Factors Influencing Trace Width

- High-voltage components and heat-sensitive parts demand precise trace width calculations based on current and desired impedance.

- Consider using the IPC2152 nomogram for controlled impedance routing to maintain optimal current-temperature relationships.

3. Temperature Rise Management

- Keeping temperature rise within 10°C is ideal to prevent excessive heat affecting surrounding components.

- Proper trace sizing is essential to avoid substrate discoloration and weakening due to high temperatures.

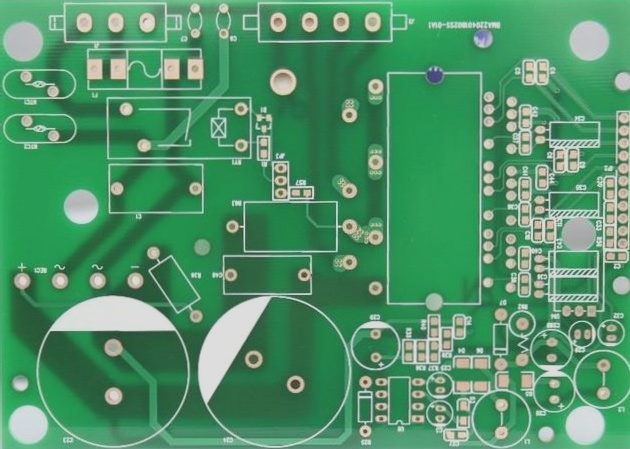

4. Selecting Trace Width

- Utilize trace width versus current tables as a starting point for sizing traces effectively.

- Consider substrate variations like aluminum core PCBs or ceramic substrates for specific application needs.

5. Calculating Trace Size

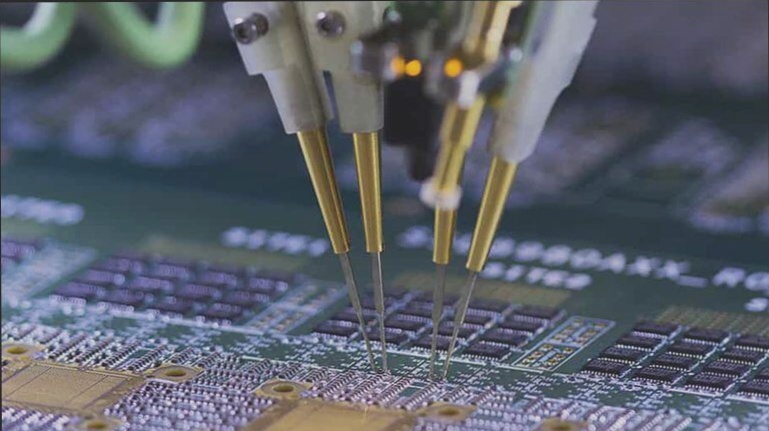

- Use formulas from the IPC-2152 standard to determine trace size based on current limits and temperature rise constraints.

- Verify trace size for different copper weights to ensure accurate current and temperature management.

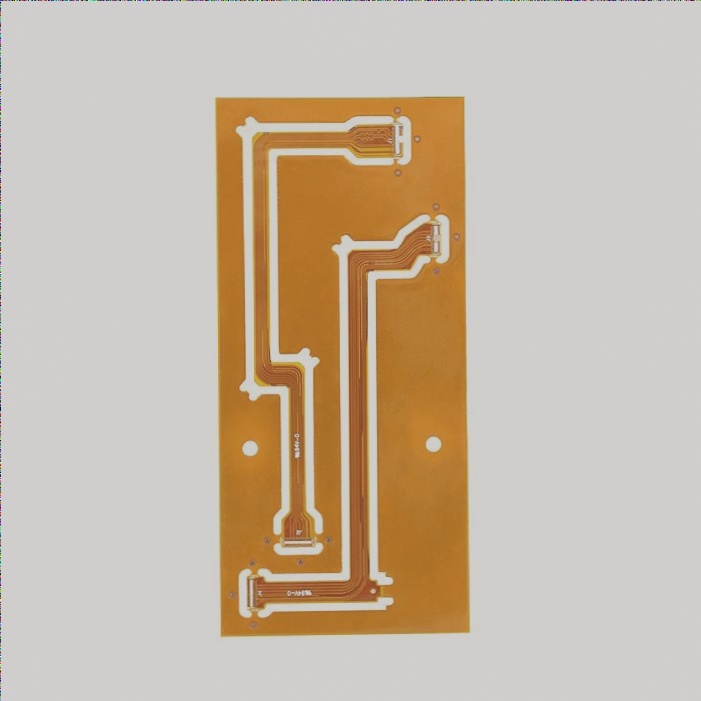

6. Enhancing Trace Cooling

- Opt for substrates with higher thermal conductivity to improve heat dissipation from traces.

- Consider the ratio of thermal conductivity between substrates for better temperature control.

By following these guidelines and utilizing tools like the IPC2152 nomogram, designers can efficiently size PCB traces to meet specific current and temperature rise requirements, ensuring optimal performance and reliability.