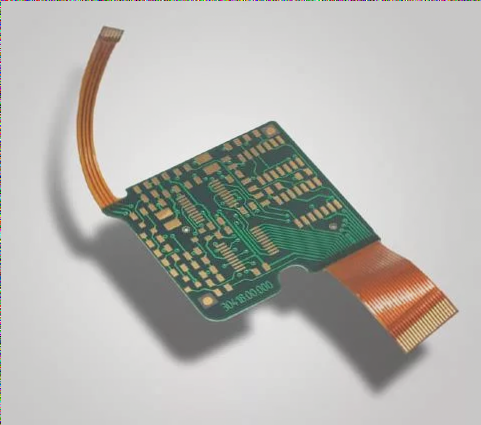

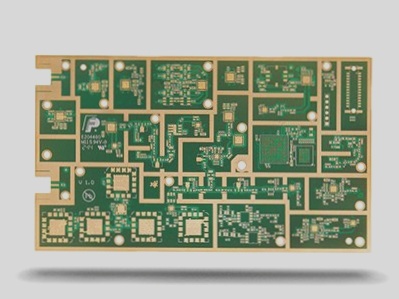

The Importance of Stiffeners in Flexible Circuit Boards

Flexible circuits, commonly known as Flex PCBs, are essential components in electronic products. Made of polyimide or polyester film, these boards are flexible but lack mechanical strength, making them prone to cracking. To address this issue, stiffeners made of materials like steel, FR4, PI, and aluminum are added to enhance the overall strength of the Flex PCB.

Mounting Methods of FPC Stiffeners

- Manual Method: Currently, manual attachment is the primary method due to the diverse types and sizes of FPCs. However, manual attachment is slow and imprecise, not meeting production demands effectively.

- Stamping Method: Stamping equipment is utilized to stamp the reinforcement board, which is then affixed to the Flex PCB. This process involves multiple complex linear motions for alignment, making it time-consuming.

- Suction Method: This method employs a gantry structure for transporting the Flex PCB to the placement position. The reinforcing sheet is then suctioned onto the board with high precision through visual recognition, ensuring accurate and rapid placement, ideal for mass production needs.

Stiffeners play a crucial role in enhancing the strength and durability of flexible circuit boards, ensuring the reliability of electronic products.