Understanding PCB Assembly (PCBA)

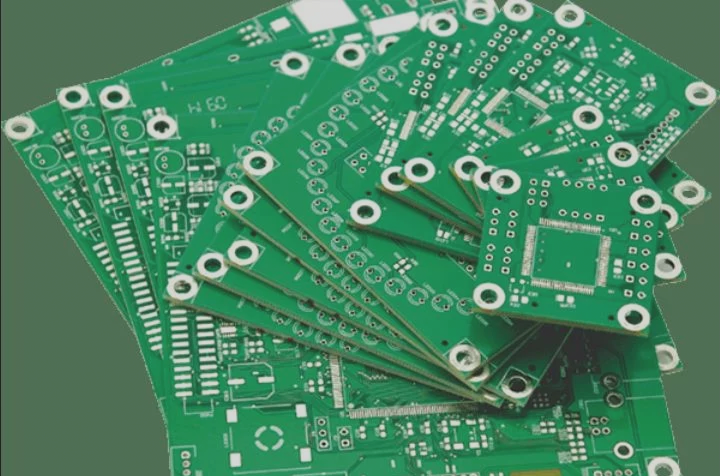

Printed Circuit Board Assembly (PCBA) is a crucial sector within the electronics industry, with the PCB’s invention and commercialization playing pivotal roles. PCBA refers to the electronic assembly based on PCB.

To grasp the evolution of the global electronic assembly industry and the formation of PCBA, it’s essential to delve into the industry’s developmental journey.

Exploring the PCB Board Assembly Process

The assembly of printed circuit boards involves collaboration among multiple teams, and sometimes external companies in the case of outsourcing. It’s imperative to follow well-defined processes with clear communication and support from all involved parties to ensure smooth production.

Effective communication from the project’s inception is key to avoiding rework and streamlining the assembly process. Engaging all stakeholders, including the assembly partner, from the product’s conception facilitates better decision-making and problem-solving.

The Significance of Component Installation

PCB assembly entails installing various components onto the board. The process includes:

- SMT (Surface Mount Technology) – components are surface-mounted

- THT (Through-Hole Technology) – components are mounted through holes

- THT + SMT – a combination of lead and surface mount

Surface mounting allows components to be directly attached to the board, maximizing the working area. On the other hand, lead-out mounting involves fixing components in plated holes on the board, with soldered contacts for secure fastening.

Considerations for THT Mounting

While THT components and mounting have their disadvantages, they are often necessary due to component size and weight. THT components require meticulous preparation, including metallization of holes for soldering.

Storage and Handling of PCB Components

Proper storage of components is critical for successful PCB assembly. Components have specific requirements for humidity and temperature control that must be strictly observed to maintain their integrity.

PCB Assembly Techniques: Solder Paste, Component Insertion, and Refusion

Introduction

When it comes to assembling electronic boards, attention to detail is crucial for a successful outcome. From applying solder paste to the insertion of components and the refusion process, each step plays a vital role in the functionality of the final product.

Solder Paste Application

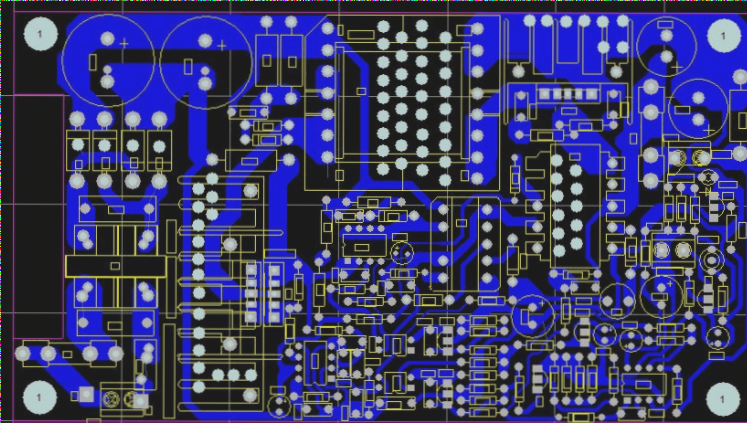

Solder paste application is a critical stage in electronic board assembly, often prone to errors if not executed with precision. Factors such as stencil quality, equipment maintenance, and cleanliness significantly impact the soldering process.

Component Insertion

Precision is key when inserting components, especially on boards with tiny or critical parts like BGAs. As technology advances, smaller components with multiple functions require meticulous handling and cutting-edge technology.

Refusion Process

Reflowing each board at the ideal temperature is essential for quality soldering without damaging the components. Finding the perfect balance in temperature is crucial to avoid irreversible damage to the final product.

PTH vs. SMD Assembly

PTH (Pin Through Hole) and SMD (Surface Mounted Device) are the two primary methods for assembling electronic board components. While PTH is cost-effective and widely used, SMD offers a more advanced and robust mounting solution without compromising board integrity.

What is PTH?

PTH assembly involves inserting component terminals into drilled holes on the board before soldering. Although considered traditional, PTH remains prevalent, especially in budget-sensitive applications.

What is SMD?

SMD technology eliminates the need for drilled holes by soldering components directly onto the board surface using advanced tools. This method provides a stronger mounting solution by avoiding weak spots created by holes.

Differences and Considerations

While SMD technology is newer, the choice between PTH and SMD assembly depends on the specific requirements of the board. Each method offers unique advantages, and understanding the differences is essential for making an informed decision.

SMD Mounting Benefits

SMD components offer economic advantages by reducing assembly time and material usage. Their smaller size and enhanced functionality make them an attractive option for compact designs.

Ultimately, the selection between PTH and SMD assembly hinges on the complexity and size constraints of the board. While PTH components are easier to solder, SMD technology provides a more versatile solution for intricate designs.

Advantages of Surface Mount Technology (SMD) over Plated Through-Hole (PTH)

- SMD components are smaller, saving space compared to PTH;

- SMD components have pads in their body for direct board surface mounting;

- Higher component density per area in SMD technology than PTH;

- SMD technology is cost-effective for large-scale production;

- Advanced design, production, features, and technologies in SMD;

- Manual welding in SMD is complex, necessitating automatic machines;

- PTH technology mainly used in prototyping.

Outsourcing electronic board assembly optimizes time, allowing focus on other business areas. The same applies to outsourcing PCB assembly!

Why Choose a Professional PCB Assembly Company?

There are numerous benefits to hiring experts for PCB assembly:

- Assured high quality through specialized professionals and advanced equipment;

- Enhanced access to components, both domestic and imported;

- Cost reduction by outsourcing assembly services.

Who Should Manage PCB Assembly Projects?

Specialized teams should handle PCB assembly projects, considering factors like component proximity and margins. Collaboration with the manufacturer from the start is crucial. External factors such as costs, market trends, and component quality are also vital, requiring interdisciplinary teamwork for cost-effective solutions.

Importance of Reliable Component Sourcing for PCB Assembly

Internalizing material purchasing for electronic board assembly can lead to issues due to component specificity. Validation and collaboration among teams are essential to avoid errors. Obsolescence and product replacements near manufacturing dates should involve technical input for successful outcomes.

Ensuring Effective PCB Assembly

Monitoring the assembly process is crucial for optimal printed circuit board creation. Conducting technical visits and assessing the assembler’s reputation are key steps in achieving the best results.

Functional Testing in PCB Assembly

Testing Phase in PCB Manufacturing

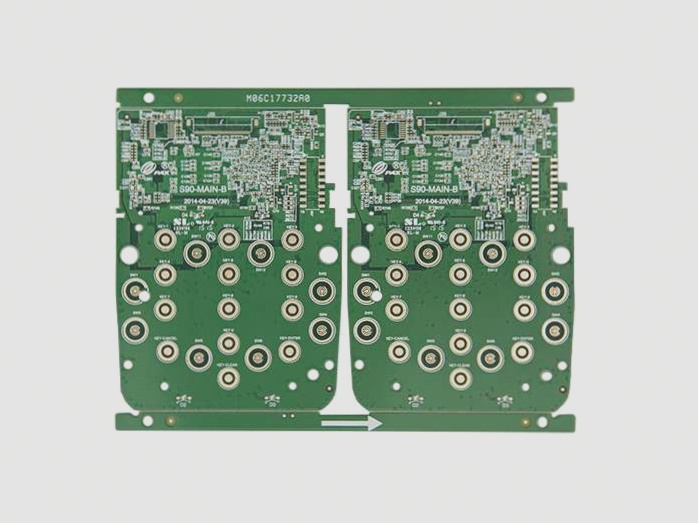

Once the printed circuit boards are manufactured, the crucial testing phase begins. Testing is essential to ensure the quality and functionality of the boards. Ideally, testing should be conducted on a sample of products or, for small batches, on every individual board. It is recommended to test the boards on the actual product as soon as possible to detect any potential interference that may only arise when all components are in place and the product is fully assembled.

Efficient Component Management

Our comprehensive component management process involves purchasing materials, prioritizing based on urgency, and sourcing from reliable suppliers. We maintain transparency with our customers throughout the procurement process, with a focus on efficient process management. Whether it involves import processes or supplier specifications, we ensure a seamless component management experience.

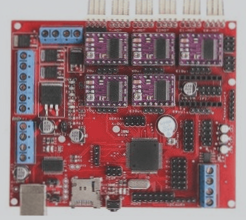

Professional SMD/PTH Plate Assembly

At WellCircuits, our skilled team and state-of-the-art equipment excel in assembling electronic components using both SMT (surface mounting technology) and THT (through hole technology). Our automated machines are capable of assembling and soldering even the most intricate components, ensuring superior quality and precision in all manufactured products.

Thorough Testing and Validation Procedures

Backed by an experienced electronic engineering team, we specialize in developing test jigs for industrialized boards. Our experts handle firmware recording and necessary adjustments for product testing. Additionally, we guide our customers through the product certification process, collaborating with relevant authorities and modifying the project as required for successful validation.

Final Product Assembly and Integration

The final stage involves integrating electronic boards into their respective enclosures, utilizing electronic component kits (SKD), integrating software, and applying finishing touches such as labeling. Our dedicated assembly area ensures systematic manufacturing of diverse equipment, encompassing everything from product assembly to packaging for a seamless end-to-end assembly process.