How to Check the Welding Quality of Circuit Boards

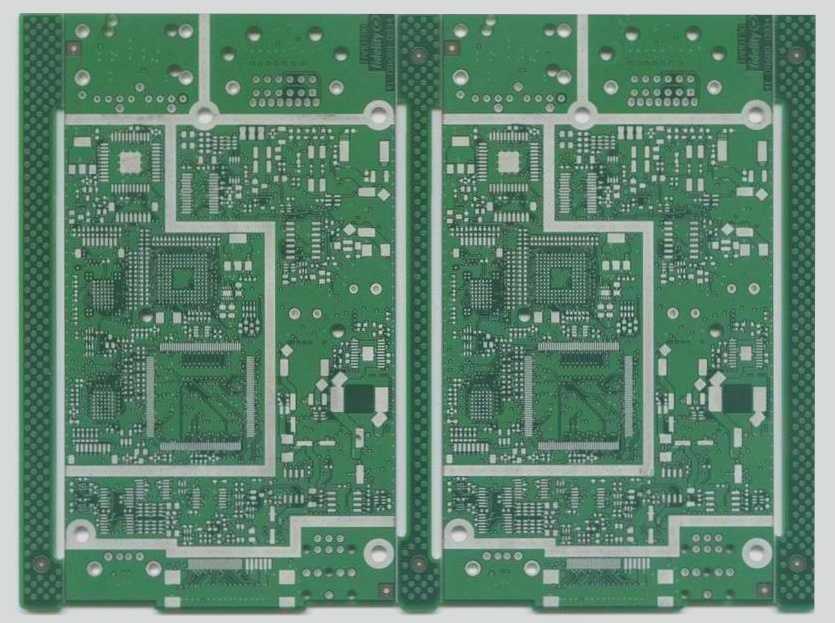

1. The Visual Method of PCB

The visual inspection method relies on the human eye to directly observe the soldering condition of the circuit board’s solder joints. It can identify issues such as poor wettability, inappropriate solder volume, pad detachment, bridging, small solder ball splashes, dull solder joints, and solder leakage. The simplest tool for visual inspection is a magnifying glass, typically a fixed magnifying glass with 5 to 10 times magnification, which is suitable for inspecting low-density circuit board soldering. However, this tool can lead to inspector fatigue. A more advanced visual inspection tool is a camera-type screen display instrument, which offers adjustable magnification up to 80 to 90 times. This device displays the soldered areas on a screen via a CCD, allowing observers to view it similarly to watching television. Higher-end instruments can automatically move the circuit board in two directions and also auto-locate to inspect critical areas of the PCBA. Additionally, these devices can be equipped with a video recorder to document the inspection results.

2. Infrared Detection Method

The infrared detection method uses an infrared beam to heat the solder joints of the circuit board, then monitors the heat release curve to determine if the solder joint has internal cavities, thus providing an indirect assessment of welding quality. This method is suitable for large-scale, automated soldering processes where the consistency of the pads is high and component sizes are relatively uniform. Otherwise, variations in heat dissipation characteristics due to other influencing factors can increase the false detection rate. Given the restrictions of this method, such as the variability in solder joint sizes across different circuit boards, its application in electronic product testing is limited.

3. **X-ray Fluoroscopy**

The X-ray fluoroscopy method for circuit boards leverages the fact that X-rays cannot pass through solder as effectively as through materials like copper, silicon, or FR-4. This technique reveals the density distribution of solder thickness, shape, and quality. It is ideal for detecting hidden solder joints. The circuit board to be tested is placed in the X-ray chamber, and the display shows how the solder joint obstructs X-ray passage, forming a contour of the joint.

4. **Online Testing Method**

The online testing method employs an on-line tester connected to the test points on the circuit board via a signal interface called a “bed of needles.” This method allows for checking open circuits, short circuits, and faulty components, as well as verifying component functions like resistance, capacitance, and transistor polarity. IC dummy solder pins can be tested using the IC floating pin test method. For circuit boards with high component density, boundary scan technology can be used to route test points to the edge connector, enabling the online tester to measure the required points at various locations.

WellCircuits is eager to be your business partner. Our goal is to become the most professional prototyping PCB manufacturer globally. With over ten years of experience, we are dedicated to fulfilling the needs of customers from various industries regarding quality, delivery, cost-effectiveness, and other demanding requirements. As one of the most experienced PCB manufacturers and SMT assemblers in China, we are proud to be your top business partner and reliable friend in all aspects of your PCB needs. We strive to make your research and development efforts seamless and stress-free.

1. The Visual Method of PCB

The visual inspection method relies on the human eye to directly observe the soldering condition of the circuit board’s solder joints. It can identify issues such as poor wettability, inappropriate solder volume, pad detachment, bridging, small solder ball splashes, dull solder joints, and solder leakage. The simplest tool for visual inspection is a magnifying glass, typically a fixed magnifying glass with 5 to 10 times magnification, which is suitable for inspecting low-density circuit board soldering. However, this tool can lead to inspector fatigue. A more advanced visual inspection tool is a camera-type screen display instrument, which offers adjustable magnification up to 80 to 90 times. This device displays the soldered areas on a screen via a CCD, allowing observers to view it similarly to watching television. Higher-end instruments can automatically move the circuit board in two directions and also auto-locate to inspect critical areas of the PCBA. Additionally, these devices can be equipped with a video recorder to document the inspection results.

2. Infrared Detection Method

The infrared detection method uses an infrared beam to heat the solder joints of the circuit board, then monitors the heat release curve to determine if the solder joint has internal cavities, thus providing an indirect assessment of welding quality. This method is suitable for large-scale, automated soldering processes where the consistency of the pads is high and component sizes are relatively uniform. Otherwise, variations in heat dissipation characteristics due to other influencing factors can increase the false detection rate. Given the restrictions of this method, such as the variability in solder joint sizes across different circuit boards, its application in electronic product testing is limited.

3. **X-ray Fluoroscopy**

The X-ray fluoroscopy method for circuit boards leverages the fact that X-rays cannot pass through solder as effectively as through materials like copper, silicon, or FR-4. This technique reveals the density distribution of solder thickness, shape, and quality. It is ideal for detecting hidden solder joints. The circuit board to be tested is placed in the X-ray chamber, and the display shows how the solder joint obstructs X-ray passage, forming a contour of the joint.

4. **Online Testing Method**

The online testing method employs an on-line tester connected to the test points on the circuit board via a signal interface called a “bed of needles.” This method allows for checking open circuits, short circuits, and faulty components, as well as verifying component functions like resistance, capacitance, and transistor polarity. IC dummy solder pins can be tested using the IC floating pin test method. For circuit boards with high component density, boundary scan technology can be used to route test points to the edge connector, enabling the online tester to measure the required points at various locations.

WellCircuits is eager to be your business partner. Our goal is to become the most professional prototyping PCB manufacturer globally. With over ten years of experience, we are dedicated to fulfilling the needs of customers from various industries regarding quality, delivery, cost-effectiveness, and other demanding requirements. As one of the most experienced PCB manufacturers and SMT assemblers in China, we are proud to be your top business partner and reliable friend in all aspects of your PCB needs. We strive to make your research and development efforts seamless and stress-free.