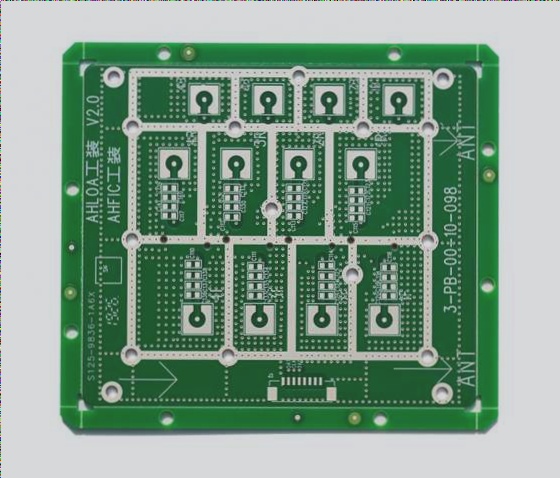

1 PCB layout largely depends on the physical structure of the circuit board, whether it uses through-hole assembly, surface mount technology (SMT), or a combination of both.

2 Through-hole assembly involves mounting components with wire leads into holes drilled in the PCB. This method is often used for larger components or those that require a strong mechanical connection.

3 Surface mount technology, on the other hand, involves mounting components directly onto the surface of the PCB. This method allows for smaller components and higher component density on the board.

4 Some circuit boards may use a combination of both through-hole and SMT components, allowing for a wider range of component options and configurations.

5 The physical structure of the circuit board also affects the routing of traces, placement of components, and overall design considerations. It is important for PCB experts to carefully consider the physical structure of the board when laying out a PCB design.

Board Layout

Board Layout: Tips for Setting

Designing a circuit board requires different grid settings at different stages. Large grid points can be used for device layout during the layout stage. For large devices such as ICs and non-positioning connectors, a grid accuracy of 50-100 mils can be selected for layout, while for passive small devices such as resistors, capacitors, and inductors, a grid accuracy of 25 mils can be used. The accuracy of large grid points is beneficial for device alignment and layout aesthetics.

Board Layout: Rules

1. In general, all components should be arranged on the same side of the circuit board. Only when the top layer components are too dense can some highly limited and low heat-generating devices, such as chip resistors, chip capacitors, chip ICs, etc., be placed on the lower layer.

2. On the premise of ensuring electrical performance, components should be placed on a grid and arranged parallel or perpendicular to each other, to be neat and beautiful. In general, components are not allowed to overlap; The arrangement of components should be compact, and the components should be evenly distributed and densely distributed throughout the entire layout.

3. The minimum spacing between adjacent solder pad patterns of different components on the circuit board should be at least 1MM.

4. The distance from the edge of the board layout is generally not less than 2MM. The optimal shape of the circuit board is rectangular, with an aspect ratio of 3:2 or 4:3. When the surface size of the circuit board is greater than 200MM by 150MM, the mechanical strength that the circuit board can withstand should be considered.

Board Layout: Techniques

In the layout design of a PCB, it is necessary to analyze the units of the circuit board and design the layout based on their functions. When laying out all components of the circuit, the following principles should be followed.

1. Arrange the positions of each functional circuit unit according to the circuit flow, making the layout convenient for signal flow and keeping the signal in the same direction as much as possible.

2. Layout around the core components of each functional unit as the center. The components should be evenly, integrally, and compactly arranged on the PCB, minimizing and shortening the leads and connections between each component as much as possible.

3. For circuits operating at high frequencies, consideration should be given to the distribution parameters between components. Generally, circuits should be arranged in parallel with components as much as possible, which is not only aesthetically pleasing but also easy to install and mass produce.

Special Components and Layout Design

Special components and layout design in PCB refer to key components in the high-frequency part, core components in the circuit, easily disturbed components, components with high voltage, components with high heat generation, and some heterosexual components. The positions of these special components need to be carefully analyzed to ensure that the layout meets the requirements of circuit functions and production needs. Improper placement of them may result in circuit compatibility issues and signal integrity issues, leading to the failure of PCB design.

When designing how to place special components, the first consideration is the size of the PCB. When the PCB size is too large, the printing lines are long, the impedance increases, the anti-drying ability decreases, and the cost also increases; When it is too small, the heat dissipation is poor, and the adjacent lines are easily disturbed. After determining the size of the PCB, determine the square position of the special components. Finally, lay out all components of the circuit according to the functional units.

The position of special components should generally follow the following principles when the layout

1. Try to shorten the connection between high-frequency components as much as possible, and try to reduce their distribution parameters and electromagnetic interference with each other. Components that are susceptible to interference should not be too close to each other, and input and output should be kept as far away as possible.

2. Some components or wires may have high potential differences, and their distance should be increased to avoid accidental short circuits caused by the discharge. High-voltage components should be kept out of reach as much as possible.

3. Components weighing over 15G can be fixed with brackets and then welded. Those heavy and hot components should not be placed on the circuit board, but on the bottom plate of the main box, and heat dissipation issues should be considered. Thermal-sensitive components should be kept away from heating components.

4. For the layout of adjustable components such as a potentiometer, adjustable inductance coil, variable capacitor, microswitch, etc., the structural requirements of the whole wrench should be considered. Some switches often used should be placed in places easily accessible to hands if the structure allows. The layout of components should be balanced, with appropriate density, and should not be top-heavy.

Importance of PCB Board Layout

The layout is crucial for electronic products, and in some PCB design teams, professional layout technicians are employed to implement best practices and avoid known placement considerations. In most cases, advanced computer-aided design (CAD) software is utilized to maximize efficiency and detect potential design issues.

PCB board layout is a key factor in creating a successful final product, rather than being implemented by many engineers during the initial design cycle. The layout is crucial for electronic products. In design, layout is an important aspect. The quality of layout results will directly affect the effectiveness of wiring, so it can be considered that a reasonable layout is the first step to a successful PCB design.

A reasonable PCB board layout can save space on the circuit board, reduce jumpers, and reduce costs.

2 Through-hole assembly involves mounting components with wire leads into holes drilled in the PCB. This method is often used for larger components or those that require a strong mechanical connection.

3 Surface mount technology, on the other hand, involves mounting components directly onto the surface of the PCB. This method allows for smaller components and higher component density on the board.

4 Some circuit boards may use a combination of both through-hole and SMT components, allowing for a wider range of component options and configurations.

5 The physical structure of the circuit board also affects the routing of traces, placement of components, and overall design considerations. It is important for PCB experts to carefully consider the physical structure of the board when laying out a PCB design.

Board Layout

Board Layout: Tips for Setting

Designing a circuit board requires different grid settings at different stages. Large grid points can be used for device layout during the layout stage. For large devices such as ICs and non-positioning connectors, a grid accuracy of 50-100 mils can be selected for layout, while for passive small devices such as resistors, capacitors, and inductors, a grid accuracy of 25 mils can be used. The accuracy of large grid points is beneficial for device alignment and layout aesthetics.

Board Layout: Rules

1. In general, all components should be arranged on the same side of the circuit board. Only when the top layer components are too dense can some highly limited and low heat-generating devices, such as chip resistors, chip capacitors, chip ICs, etc., be placed on the lower layer.

2. On the premise of ensuring electrical performance, components should be placed on a grid and arranged parallel or perpendicular to each other, to be neat and beautiful. In general, components are not allowed to overlap; The arrangement of components should be compact, and the components should be evenly distributed and densely distributed throughout the entire layout.

3. The minimum spacing between adjacent solder pad patterns of different components on the circuit board should be at least 1MM.

4. The distance from the edge of the board layout is generally not less than 2MM. The optimal shape of the circuit board is rectangular, with an aspect ratio of 3:2 or 4:3. When the surface size of the circuit board is greater than 200MM by 150MM, the mechanical strength that the circuit board can withstand should be considered.

Board Layout: Techniques

In the layout design of a PCB, it is necessary to analyze the units of the circuit board and design the layout based on their functions. When laying out all components of the circuit, the following principles should be followed.

1. Arrange the positions of each functional circuit unit according to the circuit flow, making the layout convenient for signal flow and keeping the signal in the same direction as much as possible.

2. Layout around the core components of each functional unit as the center. The components should be evenly, integrally, and compactly arranged on the PCB, minimizing and shortening the leads and connections between each component as much as possible.

3. For circuits operating at high frequencies, consideration should be given to the distribution parameters between components. Generally, circuits should be arranged in parallel with components as much as possible, which is not only aesthetically pleasing but also easy to install and mass produce.

Special Components and Layout Design

Special components and layout design in PCB refer to key components in the high-frequency part, core components in the circuit, easily disturbed components, components with high voltage, components with high heat generation, and some heterosexual components. The positions of these special components need to be carefully analyzed to ensure that the layout meets the requirements of circuit functions and production needs. Improper placement of them may result in circuit compatibility issues and signal integrity issues, leading to the failure of PCB design.

When designing how to place special components, the first consideration is the size of the PCB. When the PCB size is too large, the printing lines are long, the impedance increases, the anti-drying ability decreases, and the cost also increases; When it is too small, the heat dissipation is poor, and the adjacent lines are easily disturbed. After determining the size of the PCB, determine the square position of the special components. Finally, lay out all components of the circuit according to the functional units.

The position of special components should generally follow the following principles when the layout

1. Try to shorten the connection between high-frequency components as much as possible, and try to reduce their distribution parameters and electromagnetic interference with each other. Components that are susceptible to interference should not be too close to each other, and input and output should be kept as far away as possible.

2. Some components or wires may have high potential differences, and their distance should be increased to avoid accidental short circuits caused by the discharge. High-voltage components should be kept out of reach as much as possible.

3. Components weighing over 15G can be fixed with brackets and then welded. Those heavy and hot components should not be placed on the circuit board, but on the bottom plate of the main box, and heat dissipation issues should be considered. Thermal-sensitive components should be kept away from heating components.

4. For the layout of adjustable components such as a potentiometer, adjustable inductance coil, variable capacitor, microswitch, etc., the structural requirements of the whole wrench should be considered. Some switches often used should be placed in places easily accessible to hands if the structure allows. The layout of components should be balanced, with appropriate density, and should not be top-heavy.

Importance of PCB Board Layout

The layout is crucial for electronic products, and in some PCB design teams, professional layout technicians are employed to implement best practices and avoid known placement considerations. In most cases, advanced computer-aided design (CAD) software is utilized to maximize efficiency and detect potential design issues.

PCB board layout is a key factor in creating a successful final product, rather than being implemented by many engineers during the initial design cycle. The layout is crucial for electronic products. In design, layout is an important aspect. The quality of layout results will directly affect the effectiveness of wiring, so it can be considered that a reasonable layout is the first step to a successful PCB design.

A reasonable PCB board layout can save space on the circuit board, reduce jumpers, and reduce costs.