Creating SMD Footprints: A Step-by-Step Guide

In the previous tutorial, we covered how to create SMD pads for the 0603 footprint in Cadence Allegro. Now, let’s delve into the process of creating a footprint, using the 0603 footprint as our reference.

Footprint Specifications:

- Component: GRM033Z71C104KE14D from Murata Electronics

- Footprint Name: C0603

- Drawing Type: Package Symbol

Step-by-Step Instructions:

Step 1: Launch PCB Editor

Begin by opening the PCB Editor and selecting Allegro PCB Librarian XL.

Step 2: Create a New Footprint

In the menu bar, click “File” > “New” to create a new footprint. Enter the footprint name (C0603) and select “Package Symbol” as the drawing type.

Step 3: Set Design Parameters

Go to “Setup” > “Design Parameter” and adjust the User units to Millimeters for precision.

Step 4: Customize Grid Settings

Under “Setup” > “Grid”, modify the default grid from 2.54mm to 0.1mm for accurate placement.

Step 5: Define User References

Access “Setup” > “User References” to set the path for saving pads. Ensure proper configuration by clicking “Apply” and then “OK”.

Step 6: Add Pins

Under “Layout” > “Pins”, use the Options sidebar to add pads to the footprint.

Step 7: Finalize Placement

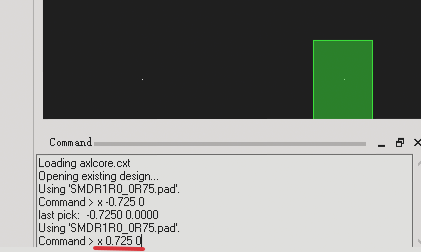

Place the pad by entering the coordinates in the command bar, followed by a right-click and selection of “Done” to complete the process.

By following these steps, you can effectively create an SMD footprint, tailored to your specific requirements.

Placing Pin Instructions for PCB Design

The process of placing pins on a PCB is crucial for proper circuit functionality. Below are the steps to follow:

Step 1: Placing Pin 1

To start, carefully position pin 1 on the designated spot. Refer to the image below for guidance:

Step 2: Placing Pin 2

Once pin 1 is secured, proceed to place pin 2 accurately. Use the image reference for assistance:

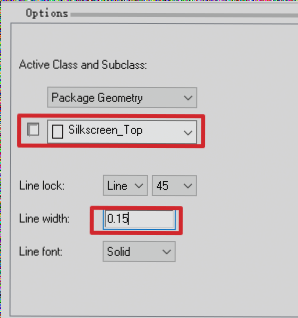

Step 3: Adding Silkscreen Outline

Enhance the PCB design by adding a silkscreen outline. Follow these steps:

- Click “Add” and select “Line” to define the layer and line width.

- Choose “Package Geometry” > “Silkscreen_Top” in the Options menu.

- Set the silkscreen line width to 0.15mm for precision.

Observe the visual representation of the completed silkscreen drawing below:

Mastering the pin placement and silkscreen outlining is fundamental in creating a well-executed PCB layout. Ensure accuracy and attention to detail for optimal results.