Creating High-Quality PCB Boards: Key Considerations

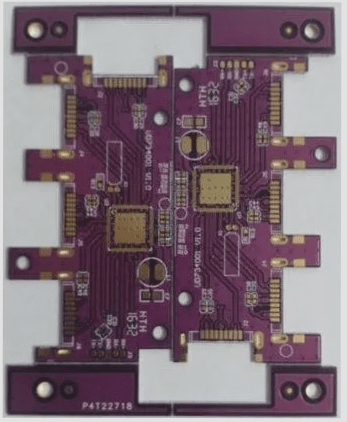

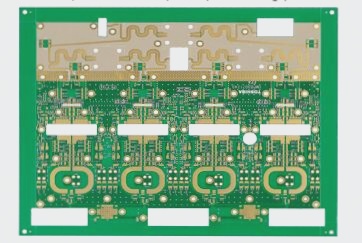

Transforming a well-designed PCB schematic into a functioning circuit board is a crucial process in microelectronics. While the concept may seem straightforward, the challenges lie in implementing the design effectively. Ensuring the creation of a high-quality PCB involves careful attention to detail and expertise.

Challenges in PCB Manufacturing

Two primary challenges in microelectronics are handling high-frequency signals and weak signals. The quality of PCB manufacturing plays a vital role in addressing these challenges. Even with identical designs, components, and schematics, PCBs from different manufacturers can yield varying results.

Ensuring High-Quality PCB Creation

- Clarify Design Objectives: Define the design goals clearly based on the type of PCB required. Special attention should be given to high-frequency signals and weak signals to minimize interference and ensure signal integrity.

- Consider Board Commissioning: Plan for board commissioning during the design phase by considering test point placement, isolation, and other relevant factors to facilitate testing of small and high-frequency signals.

- Understand Layout and Routing Requirements: Different components have specific layout and routing requirements. For instance, analog signal amplifiers require a stable power supply with minimal ripple, and components like GLINK chips necessitate special considerations for heat dissipation.

Additional Insights

When dealing with weak signals in the millivolt or microvolt range, proper shielding is essential to maintain signal integrity and prevent interference. Attention to detail in the layout and routing of components is crucial to the overall performance of the PCB.

The Importance of Component Placement in PCB Design

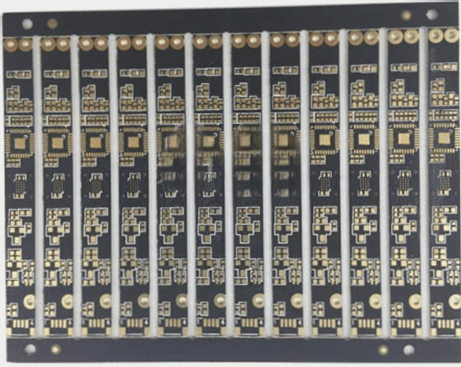

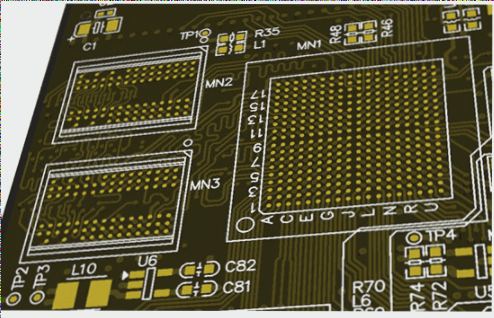

When designing a PCB, one of the primary considerations is the electrical performance of the components. It is crucial to place components that are closely connected near each other, especially for high-speed circuits. Power and small signal components should be placed separately, and the trace lengths for high-speed signals should be minimized to ensure optimal performance.

Neat and Organized Arrangement

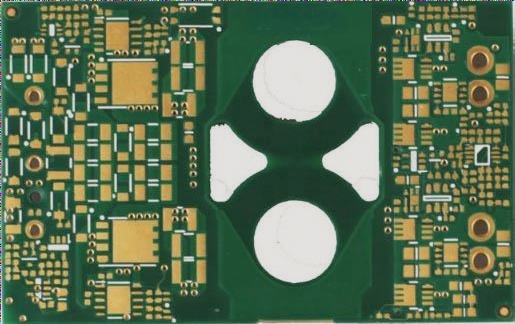

While meeting the circuit performance requirements, it is essential to arrange components neatly to facilitate easy testing. The mechanical dimensions of the board and the placement of connectors should also be carefully planned to ensure seamless integration.

Grounding and Signal Transmission

In high-speed systems, grounding and signal transmission delay times are top priorities in system design. The transmission delay on signal lines significantly impacts the overall system speed, especially for high-speed ECL circuits. It is crucial to minimize delays and ensure synchronous components are placed on the same board to avoid synchronization issues.

Considerations for Routing

As technology advances, the need for high-speed signal routing becomes more critical. Understanding transmission lines and their impact on signal integrity is crucial for designing efficient PCBs. It is essential to minimize trace lengths, especially for ultra-high-speed circuits, to prevent signal distortion.

- Transmission Line: Long signal traces on a PCB should be treated as transmission lines to suppress reflections and ensure signal integrity. While longer traces may be suitable for some circuits, ultra-high-speed circuits require careful consideration to maintain optimal performance.

If you have any PCB manufacturing needs, feel free to contact me.