PCB Design Best Practices for Engineers

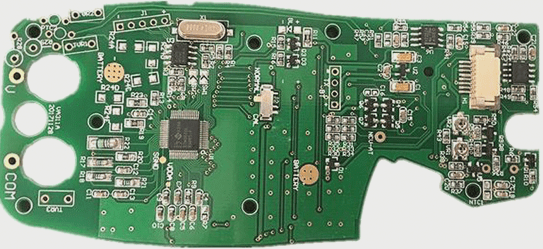

When designing PCB data, engineers at the PCB supplier must pay close attention to details. Factors such as surface treatment process, solder mask color, character color, via processing method, plug hole, cover oil, and window processing all play a crucial role in PCB design.

Board-Making Process Considerations

- Choose the right board material

- Ensure correct board thickness and installation methods

- Proper layout and wiring of components

Failure to address these factors can lead to unreliable PCB performance, early failure, or complete malfunction. While multi-layer boards offer design advantages, simpler structures with fewer layers often provide higher reliability.

Optimizing Wiring for Performance

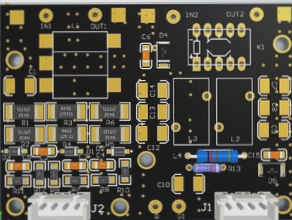

Efficient wiring is essential for optimal electronic circuit performance. Careful layout of packaged devices and wire connections is key. To create high-quality PCB boards cost-effectively and quickly, designers should follow these principles:

- Aesthetically depict electrical schematic connections

- Avoid “short circuit” and “open circuit” errors

While wiring can be done manually, computer-aided design (CAD) offers advantages for complex designs. Manual wiring allows for flexibility and the utilization of the PCB supplier’s expertise.