Identifying Potential Causes of PCB Short Circuits

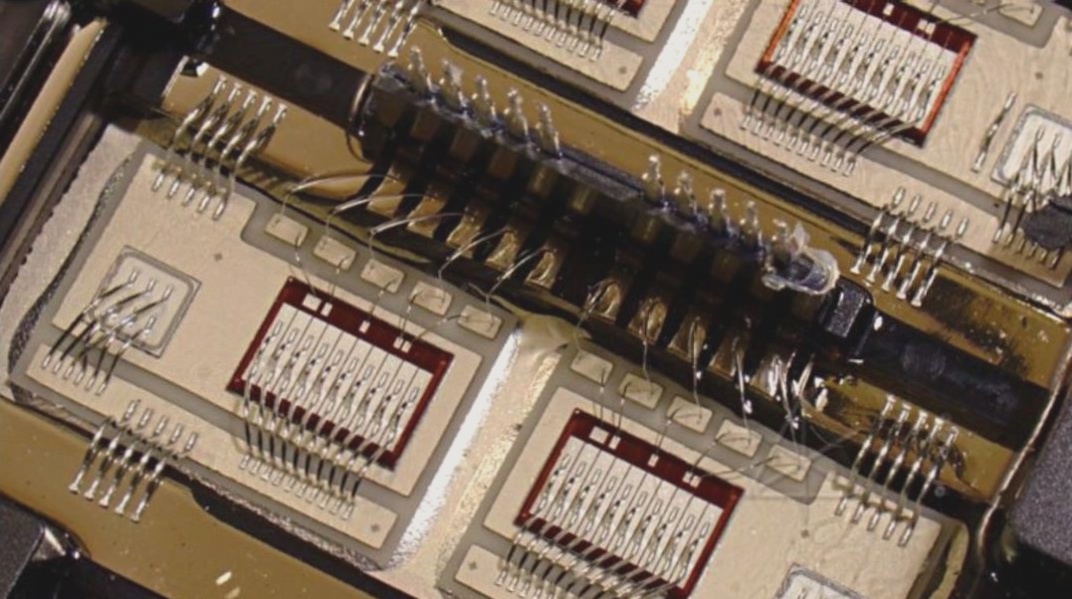

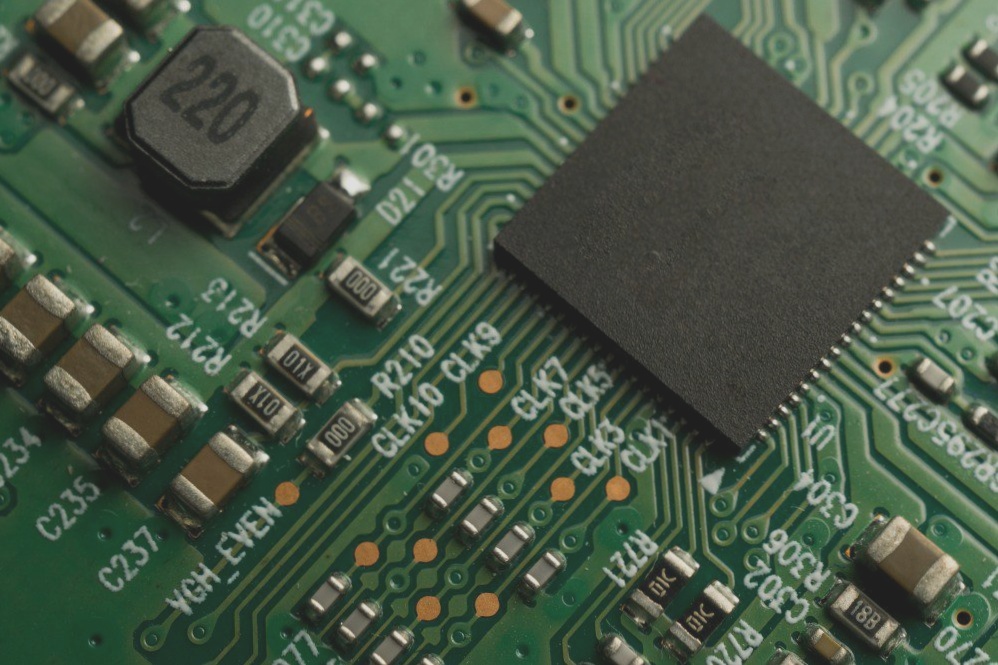

In Wuxi SMD processing, encountering a short circuit on a PCB circuit board can result in irreversible damage. This issue can arise due to various factors, including subpar PCB quality or mishandling during production. When investigating a potential short circuit on a PCB board, a simple visual inspection can be the first step. However, for a more precise diagnosis, utilizing test instruments is recommended. Here are two effective methods to pinpoint the root causes of PCB short circuits:

1. Test with a Digital Multimeter

- To determine if a circuit board is short-circuited, you should measure the resistance between different points on the circuit using a digital multimeter. If a visual inspection doesn’t uncover the short circuit’s location or cause, employing a multimeter can help trace the issue on the printed circuit board.

- For this method, you’ll need a high-quality multimeter with milliohm sensitivity. A multimeter equipped with a buzzer function can simplify the process by alerting you to any detected short circuits.

- When measuring resistance between adjacent traces or pads on a PCB, anticipate high resistance values. Unexpectedly low resistance between two conductors in a separate circuit may indicate internal or external bridging.

2. Relative to the Ground Test

- Short circuits involving ground vias or ground planes are particularly critical. In a multilayer PCB with an internal ground plane, inspecting all vias and pads on the surface layer near ground connections can help identify potential issues.

- By placing one probe on the ground connection and touching the other probe to different conductors on the board, you can test for minimal resistance. Pay attention to the board layout to avoid misinterpreting a short circuit as a common ground connection.

- Unconnected bare conductors should exhibit high resistance compared to the common ground connection. If a conductor shows very low resistance to ground without inductance, it may indicate damage or a short circuit.

Wuxi SMD processing is widely utilized in the electronics industry due to its numerous benefits. Detecting and resolving PCB short circuits promptly is crucial to avoid nullifying previous efforts. Apart from the aforementioned methods, there are other approaches available to identify short circuit causes, such as resistance measurements using a multimeter. Choose an appropriate detection method based on the specific circumstances to ensure efficient troubleshooting.