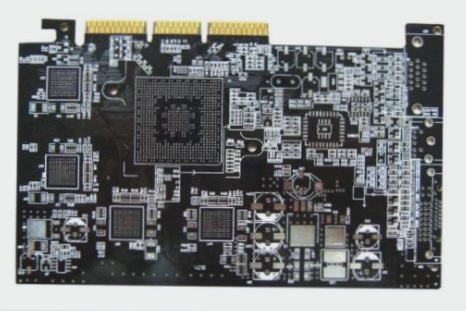

Multilayer board specifications

Trace width is crucial because it ensures that traces (whether for power or signal) operate as required, providing optimal functionality for the printed circuit board. Generally, the trace width carrying a logo may be narrower than the trace used for current.

Customers ordering multilayer printed circuit boards can cut related costs or buy at lower prices by ensuring manufacturers reduce trace widths and spacing. Many customers fail to realize that trace width and pitch issues at the design stage can significantly affect PCB costs. To keep manufacturing costs low, choose a size that allows ample space for layout completion.

Be aware that closer spacing increases the cost of PCB manufacturing. Although traces and width spacing are essential, especially in multilayer printed circuit boards, it is crucial to minimize traces and spacing to reduce costs.

### Trace Width and Spacing

1. The trace width is crucial as it ensures that the trace (whether for power or signal) operates correctly while optimizing the functionality of the printed circuit board. Generally, the trace width carrying the logo can be smaller than the trace width for current-carrying purposes.

2. Customers ordering multilayer printed circuit boards can reduce costs by ensuring that manufacturers minimize trace widths and spacing. Unfortunately, many customers do not realize that trace width and pitch issues at the design stage can significantly impact PCB costs. To keep manufacturing costs low, select a size that provides sufficient space for layout completion.

3. Be aware that reduced spacing increases the manufacturing cost of the printed circuit board design. Although trace width and spacing are essential, particularly in multilayer printed circuit boards, minimizing them is necessary to control costs.

### Electroplating and Finishing

4. Another cost factor in multilayer printed circuit boards is the expense associated with plating and finishing. Some finishes, while extending the shelf life of high-end multilayer PCBs, also raise manufacturing costs. HASL (Hot Air Solder Leveling) is one of the most cost-effective finishes available.

5. To reduce multilayer PCB production costs, opt for less expensive plating and finishing methods. Not all finishing options are affordable; for instance, processes like electroless nickel immersion gold can be costly, especially with limited budgets.

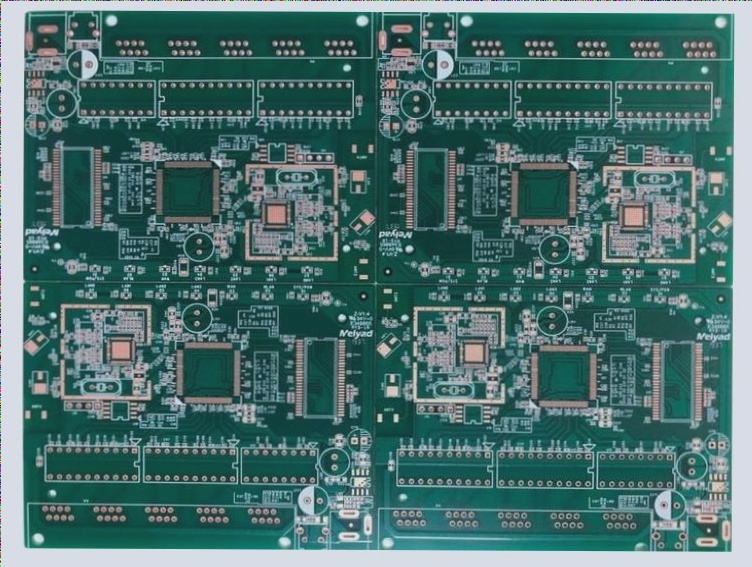

### Mass Production

6. Before mass production became widespread, creating most multilayer PCB products heavily relied on initial orders. With the advent of mass production, companies benefit from economies of scale. In essence, batch manufacturing lowers costs compared to producing individual parts.

7. This principle applies to multilayer printed circuit boards as well. To lower manufacturing costs, produce PCBs in batches, thereby reducing the total cost per unit.

### Limit the Number of Geometric Figures

8. To reduce the cost of multilayer printed circuit boards, minimize the complexity of geometric shapes. Geometry encompasses details such as the dielectric substrate, reference planes, and traces in the PCB stack.

9. Larger geometries often result in higher costs, particularly for large quantities of printed circuit boards. Although bigger geometries may yield better results, be prepared for higher costs if opting for more complex designs.

### Adhere to Recommended Tolerances

10. While strict tolerances, especially for PCB thickness, can enhance performance, they also increase manufacturing costs.

11. As a cost-conscious customer, select only the strict tolerances necessary for PCB design and performance. To manage costs effectively, consider limiting the board thickness to a recommended tolerance range.

### Maintain Sufficient Spacing Between Copper Layers

12. Using more than half an ounce of copper in inner layers and close to one ounce in outer layers of a printed circuit board significantly raises manufacturing costs.

13. To lower the cost of multilayer PCBs, ensure sufficient spacing between copper layers. Direct manufacturers to use thicker copper if necessary. Excessive spacing between copper layers can lead to increased component usage, thereby escalating manufacturing costs.

### Multilayer PCB Manufacturing – Drilling Size

14. The type of equipment used for drilling holes in printed circuit boards is crucial. While laser drills offer speed and flexibility, they also increase manufacturing costs.

15. To significantly cut costs, consider using standard drill sizes instead of laser drills, unless lasers are necessary. Larger hole diameters are preferable in multilayer PCB manufacturing due to their lower accuracy requirements, thus reducing overall costs.

### Multilayer PCB Manufacturing – Material Selection

16. Finally, material choice for manufacturing printed circuit boards, especially multilayer ones, impacts production costs. Factors affecting material selection include temperature reliability, thermal performance, signal integrity, heat transfer, and mechanical properties.

17. For high-frequency applications, advanced materials are often required. If working with a limited budget, opt for cost-effective materials suitable for your application. High-end equipment and excellent surface finishes will increase production costs, so be prepared for the associated expenses.