PCB Assembly Testing Guidelines

When testing a PCB assembly, it is crucial to follow specific guidelines to ensure accurate results and product quality.

Test Sample Usage

- Test samples should be actual soldered products to secure the thermocouple test end.

- Each test sample should be used a maximum of two times to maintain accuracy.

- Avoid prolonged usage of the same test sample for extended testing.

Color Changes in PCB

Due to high-temperature soldering, the PCB’s color may darken, affecting temperature measurement accuracy.

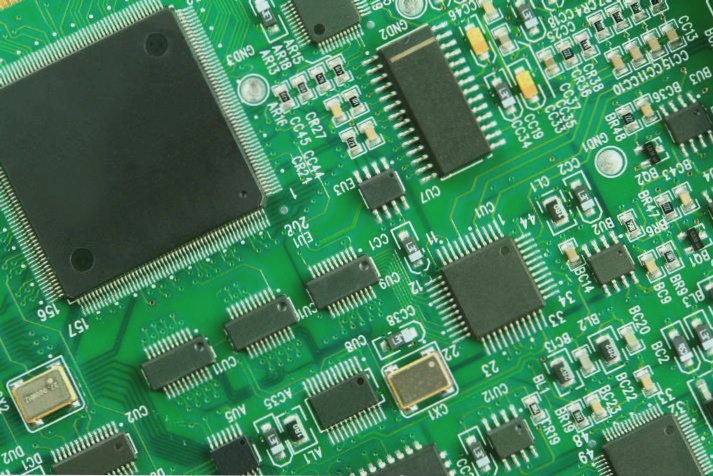

Selecting Test Points

Choose representative test points based on PCB complexity and collector channels.

- Identify hot spots in the center and cold spots around large components.

Attaching Thermocouples

Securely attach thermocouples using high-temperature solder or tape for accurate readings.

Testing Process

- Place the PCB assembly in the reflow oven and initiate the temperature curve test program.

- Monitor the real-time temperature curve as the PCB progresses through the oven.

- Review the temperature curve and peak temperature schedule post-testing.

If you require PCB manufacturing services, feel free to contact us.