The Growing Demand for FPC/PCB Circuit Boards

With the increasing need for FPC/PCB circuit boards in the mobile phone, electronics, and communication industries, there is a rise in both supply and demand for these products. However, intense price competition has caused raw material costs for FPC/PCB boards to escalate.

Challenges in the FPC/PCB Market

Manufacturers are now focusing on reducing costs to stay competitive, potentially compromising product quality. Lower-priced FPC/PCB boards may be more prone to issues like cracks and scratches, affecting overall performance.

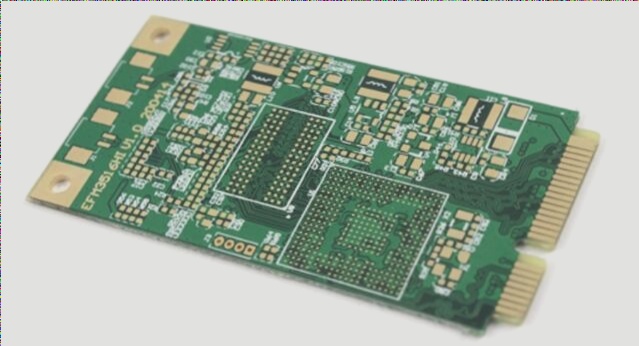

Assessing FPC/PCB Circuit Boards

When evaluating FPC/PCB boards, it is essential to consider their appearance and quality standards. Here are key factors to look out for:

- Size and Thickness Standards: Verify the dimensions and thickness of the boards to ensure they meet requirements.

- Light and Tone: Adequate printing ink coverage is crucial for insulation properties.

- Soldering Quality: Proper soldering is vital to prevent component detachment.

Criteria for High-Quality FPC/PCB Boards

For superior FPC/PCB boards, certain criteria must be met to ensure optimal performance and durability:

- User-Friendliness: Ensure proper electrical connections post-installation.

- Line Specifications: Meet standards for line width, thickness, and spacing.

- Adhesion of Copper Layers: Copper should withstand high temperatures without peeling.

- Oxidation Resistance: Prevent copper surface oxidation to avoid early failures.

- Electromagnetic Compatibility: Minimize electromagnetic radiation.

- Shape Integrity: Maintain shape integrity to prevent deformation during installation.

- Environmental Resistance: Consider factors like temperature and humidity.

- Mechanical Property Standards: Ensure mechanical properties meet installation requirements.