The Growing Importance of Quality PCB Boards in the Evolving Electronics Industry

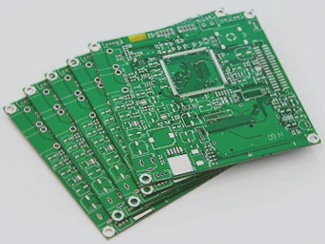

With the ever-expanding mobile phone, electronics, and communication sectors, the PCB board industry is experiencing significant growth. As the demand for advanced features like increased layers, precision, and reliability rises, ensuring top-notch quality in PCB boards becomes crucial.

Challenges in the Current PCB Market

In today’s competitive market, the quest for cheaper PCB materials has become a common trend among manufacturers. However, opting for extremely low prices often compromises the quality of materials and manufacturing processes. This trade-off can result in issues such as cracks, scratches, and subpar performance, impacting the overall reliability of the final product.

Key Factors for Assessing PCB Quality

- Size and Thickness Standards: It is essential to verify if the PCB board meets the required thickness standards. Customers should compare the dimensions with industry benchmarks to ensure compliance.

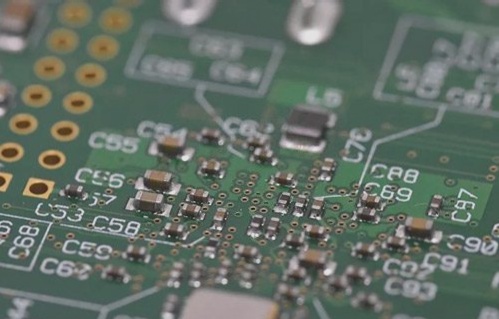

- Light and Color Evaluation: The external coating of the circuit board plays a vital role in insulation. Dull colors or uneven ink coverage may indicate insulation quality issues that need attention.

- Solder Joint Inspection: Proper soldering is critical for component attachment. Weak solder joints can lead to component detachment and impact performance. Thoroughly examining solder joints is crucial for durability and reliability.

By considering these visual cues, customers can effectively evaluate the quality of PCB boards, leading to enhanced performance and reliability in their electronic devices.