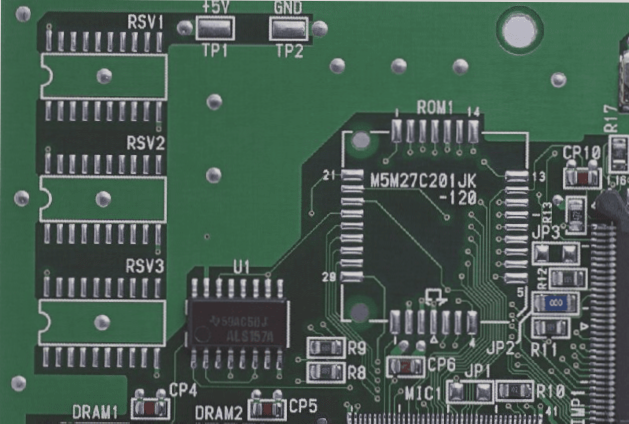

The Growing Importance of High-Quality PCB Boards in Today’s Electronics Industry

As the mobile phone, electronics, and communication sectors continue to advance rapidly, the demand for superior PCB boards has surged. Consumers now seek boards with more layers, precision, diverse materials, colors, and enhanced reliability, posing challenges for the industry.

Challenges Faced by the PCB Board Industry:

- Market price competition driving down material quality

- Manufacturers compromising on quality to offer lower prices

- Reduced reliability and performance of inferior products

- Impact on solderability and overall product quality

Assessing the Quality of PCB Circuit Boards:

To determine the quality of PCB boards, it is crucial to evaluate both appearance and specific quality specifications. Here are key factors to consider:

Assessing Appearance:

- Light and color: Brightness and ink quantity indicate insulation quality

- Size and thickness: Matching standard specifications is essential

- Welding quality: Poor welding affects overall board performance

Key Quality Requirements:

- Copper surface resistance to oxidation

- Easy post-installation component connections

- High-temperature resistance of copper skin

- Line dimensions to prevent overheating and short circuits

- Minimization of electromagnetic radiation

- Resistance to high temperatures, humidity, and special environments

- Prevention of shape deformation for proper installation alignment

- Mechanical properties meeting installation requirements

WellCircuits Limited: Your Trusted PCB Board Manufacturer

WellCircuits Limited specializes in crafting high-precision circuit boards tailored to diverse customer needs. Their product range includes double-sided, multi-layer, and thick copper boards, providing solutions for HDI, backplanes, rigid-flex designs, and more.