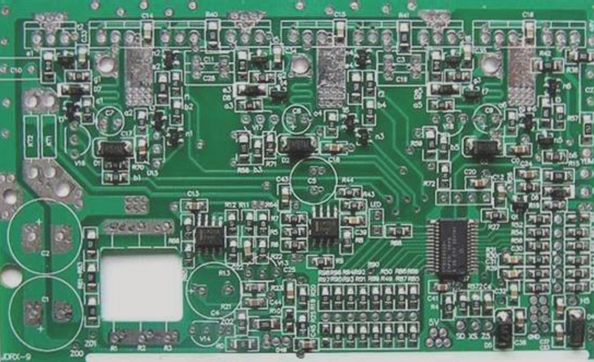

Advanced Technologies for PCB Testing

- Various technologies have emerged to streamline the testing process for PCBs, reducing costs and time to market while ensuring comprehensive fault coverage.

- Optical inspection can confirm component part numbers and orientations.

- X-ray inspection assesses solder joint quality.

- Online testing measures individual components.

- Boundary scan testing evaluates components and interconnections.

- Functional testing identifies elusive failures and verifies proper circuit board operation.

Efficient Testing Strategies

Deploying testing equipment early in the manufacturing process can help detect failures promptly, saving costs and time. For instance, utilizing an optical inspection system to verify diode polarity before solder reflow can prevent the need for rework and additional inspections later on.

Testability Analysis Tools

Complex circuit boards with numerous components can present challenges in identifying individual issues. Testability analysis tools offer invaluable assistance in managing product complexity, potentially saving up to $1 million and shortening time-to-market by three weeks.

Standardization Efforts

Standard formats, like the XML schema in version 2.0, aim to facilitate seamless data transmission between various stakeholders in PCB manufacturing. The GenCAM standard enhances collaboration between design shops, manufacturers, and test companies to ensure product quality.

Proprietary Tool Evaluation

While standards-based products offer benefits, proprietary tools like Agilent Technologies’ AwareTest and Teradyne’s D2B software series often lead in performance and functionality. These tools optimize test distribution and inspection functions, enhancing overall test coverage and efficiency.

AwareTest xi: Optimizing PCB Testing with Agilent and Teradyne Solutions

AwareTest xi suggests combining X-ray inspection with online testing for efficient PCB testing. Agilent offers a complexity index calculation to determine the best testing solution for your needs.

Agilent’s Complexity Index Calculation:

- Complexity index = [(C + J)/100] * D * M * S

- C = number of components

- J = number of solder joints

- S = 1 for double-sided PCB, 0.5 for single-sided PCB

- M = 1 for high mixture, 0.5 for low mixture composition

- D = 0.01 times the number of joints per square inch

Agilent’s recommendations based on complexity index:

- High index (above 125): Combine X-ray inspection with online testing

- Medium index (between 50 and 125): Combine X-ray or optical inspection with online testing

- Low index (less than 50): Use optical inspection or online testing

Teradyne’s D2B Software for Enhanced Testing:

Teradyne’s assembly testing department has extended its D2B software to support the Optima automatic optical inspection (AOI) platform, complementing X-ray inspection and online testing capabilities.

The D2B software features:

- GR Force/A3: Extracts data from over 30 CAD design formats to create programs for testing equipment, aiding in early design cycle analysis.

- GR Force/Strategist: Analyzes PCB designs, simulates production line setups, and determines optimal programming strategies.

- GR Force DesignView: Imports board schematic information in HPGL format, allowing easy browsing of complex design data.