Essential Skills for Mastering PCB Layout

- Understanding fundamental circuit principles is crucial for PCB Layout. Refer to “Basics of Circuit Analysis” for guidance.

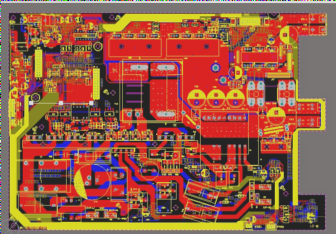

- Choosing the right design tool is important. Cadence is recommended for its power and user-friendly interface, especially for advanced circuit board technology.

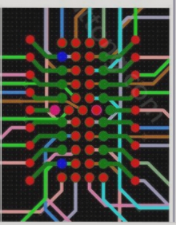

- Utilize Cadence for schematic capture to ensure effective Placement, which plays a significant role in successful PCB design.

Optimizing PCB Design

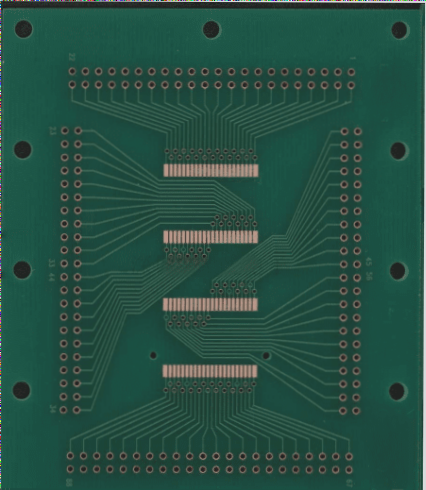

- Efficiently utilize PCB space based on the schematic diagram for optimal signal paths and routing area.

- Design a reasonable PCB stackup to balance signal quality, cost, and wiring complexity.

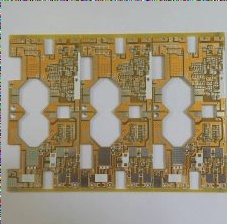

- Understand manufacturer capabilities to ensure practicality and cost-effectiveness in PCB production.

- Obtain quotes early in the design process to consider costs and ensure competitive pricing for the final product.

- Thoroughly inspect the completed PCB for various factors like impedance matching, wiring integrity, and fabrication capabilities.

- Generate fab files and deliver them to manufacturers for production.

- Select components based on the schematic, considering cost, delivery times, and impact on placement to optimize PCB space.

Mastering these skills will enhance your proficiency in PCB Layout and lead to successful circuit board designs.