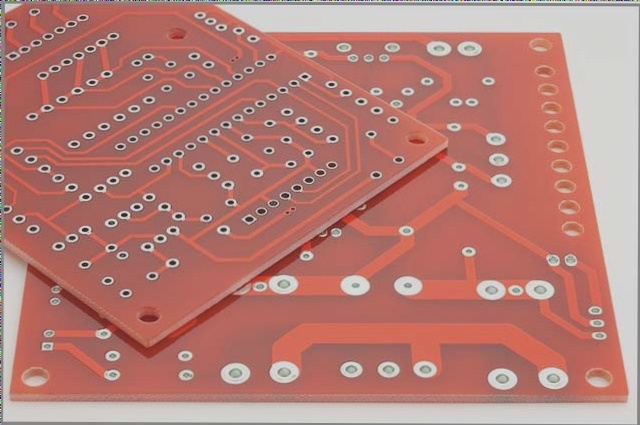

How to Mitigate Risks in PCB Design Process

Understanding and addressing potential risks in the PCB design process is crucial for ensuring the success of electronic projects. By following certain strategies and utilizing the right tools, you can significantly enhance the success rate of PCB designs. Here are some key techniques to reduce risks in PCB design:

1. Utilize Simulation Software

Simulation software can be used to evaluate specific traces on the PCB and determine if the signal quality meets the necessary requirements. By simulating signal integrity, designers can gain valuable insights into potential issues and make informed decisions.

2. Consider Signal Integrity Early

Signal integrity issues should be taken into account during the initial system planning stage. It is essential to assess whether signals can be accurately transmitted between PCBs. With a basic understanding of signal integrity principles and the use of software tools, engineers can preemptively address potential signal integrity challenges.

3. Implement Risk Control Throughout Manufacturing

Effective risk control is vital during the entire PCB manufacturing process. While simulation software can help identify some risks, designers must remain vigilant and proactive in risk mitigation. A comprehensive understanding of signal integrity principles is key to identifying and addressing potential risks effectively.

By incorporating these strategies into the PCB design process, companies can reduce risks, minimize errors, and streamline the debugging phase. By proactively managing risks, designers can enhance the overall success rate of PCB designs and improve project outcomes.