1. The development trend of PCBA labor and materials

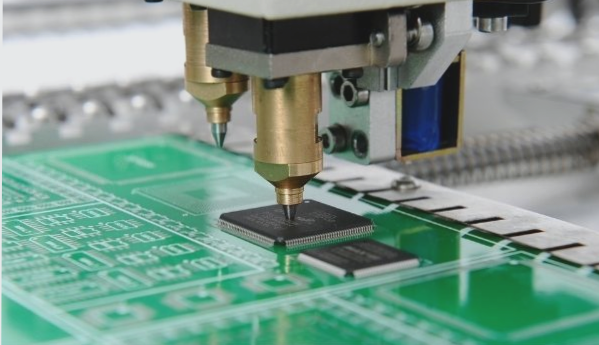

1. The PCBA package of labor and materials necessitates that the foundry possesses the capability to analyze and resolve design issues.

The pace of electronic product development is accelerating, leading to shorter product life cycles. Often, there isn’t enough time for extensive laboratory validation on the product side; products are introduced into production once basic functionalities are established. Consequently, suppliers contracted for labor and materials are confronted with R&D and design challenges during the production phase. For instance, some components may be improperly selected, or certain PCB circuit designs may have flaws. To address these challenges, foundries engaged in labor and materials contracting must enhance their production processes and technical service capabilities.

2. The management and control of PCBA labor and material components have gradually shifted from model control to functional control.

In the contracting process for labor and materials, encountering alternative materials is often unavoidable. Previously, the focus was primarily on selecting interchangeable components for cost reduction or emergency replacements. However, a more innovative strategy involves substituting certain functions with updated versions to achieve a functional leap and enhance product quality. For instance, the original LM2596 switching power supply solution, due to its relatively relaxed requirements for power supply ripple, can be replaced with the LM2576, which operates at a lower switching frequency. This approach considers the customer’s product characteristics and usage environment, rather than being confined by rigid parameters. This shift enables the improvement of component management and control from model parameters to functional objectives, ultimately creating value for customers!

3. PCBA contracting for labor and materials has evolved from merely contracting these services to offering upgrade and replacement programs.

As product competition intensifies and upgrades accelerate, major customers increasingly expect foundries to provide developmental work alongside contract labor and materials production. Given that foundries possess extensive knowledge of the electrical performance of the products they manufacture and test, they can manage product upgrades effectively without major changes—focusing instead on size, power consumption, stability, user experience, and cost. Consequently, foundries must invest in PCB production, power supply design, and stability design to meet customer demands confidently.

2. Precautions for PCBA labor and materials

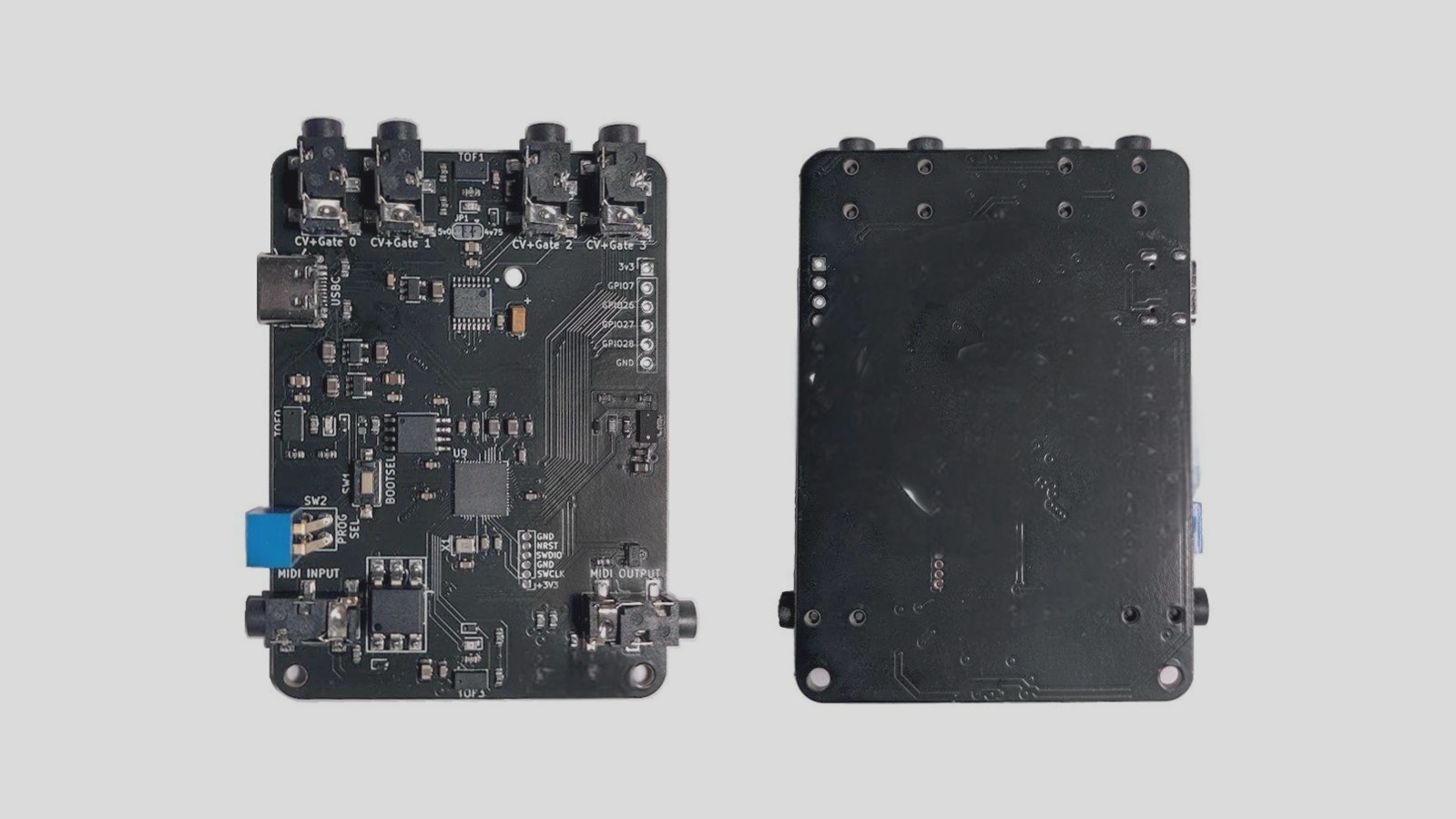

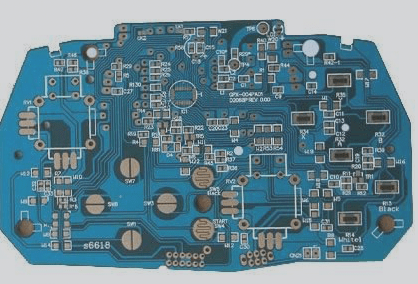

1. Line Design

A robust circuit design is the foundation of a successful PCBA. Designing the circuit according to the actual needs of the product is essential. However, some engineers may overlook the practical processing challenges during the design phase. The processing costs for functionally identical boards can vary significantly due to differing complexities, which may hinder the efficiency and performance of the electronic circuit board in production.

2. Material Selection

For PCBA packaging, the choice of materials is crucial for ensuring quality, including the circuit board material and electronic component selection. To produce a high-quality board, careful material selection is vital. Specifications for the board’s processes and materials can be requested directly, while procurement of components can be guided by standards and price ranges. Additionally, critical components should be sourced from reputable commercial brands. Often, quotes for labor and materials exceed the expected budget of the contracting party, necessitating targeted communication between the R&D enterprise and the PCBA processing facility. High-quality components cannot be sourced at the price of inferior products. If cost control is necessary, collaboration with the processing plant’s purchasing staff is essential to explore ways to reduce expenses while maintaining product quality.

—

Let me know if you need further adjustments!

1. The PCBA package of labor and materials necessitates that the foundry possesses the capability to analyze and resolve design issues.

The pace of electronic product development is accelerating, leading to shorter product life cycles. Often, there isn’t enough time for extensive laboratory validation on the product side; products are introduced into production once basic functionalities are established. Consequently, suppliers contracted for labor and materials are confronted with R&D and design challenges during the production phase. For instance, some components may be improperly selected, or certain PCB circuit designs may have flaws. To address these challenges, foundries engaged in labor and materials contracting must enhance their production processes and technical service capabilities.

2. The management and control of PCBA labor and material components have gradually shifted from model control to functional control.

In the contracting process for labor and materials, encountering alternative materials is often unavoidable. Previously, the focus was primarily on selecting interchangeable components for cost reduction or emergency replacements. However, a more innovative strategy involves substituting certain functions with updated versions to achieve a functional leap and enhance product quality. For instance, the original LM2596 switching power supply solution, due to its relatively relaxed requirements for power supply ripple, can be replaced with the LM2576, which operates at a lower switching frequency. This approach considers the customer’s product characteristics and usage environment, rather than being confined by rigid parameters. This shift enables the improvement of component management and control from model parameters to functional objectives, ultimately creating value for customers!

3. PCBA contracting for labor and materials has evolved from merely contracting these services to offering upgrade and replacement programs.

As product competition intensifies and upgrades accelerate, major customers increasingly expect foundries to provide developmental work alongside contract labor and materials production. Given that foundries possess extensive knowledge of the electrical performance of the products they manufacture and test, they can manage product upgrades effectively without major changes—focusing instead on size, power consumption, stability, user experience, and cost. Consequently, foundries must invest in PCB production, power supply design, and stability design to meet customer demands confidently.

2. Precautions for PCBA labor and materials

1. Line Design

A robust circuit design is the foundation of a successful PCBA. Designing the circuit according to the actual needs of the product is essential. However, some engineers may overlook the practical processing challenges during the design phase. The processing costs for functionally identical boards can vary significantly due to differing complexities, which may hinder the efficiency and performance of the electronic circuit board in production.

2. Material Selection

For PCBA packaging, the choice of materials is crucial for ensuring quality, including the circuit board material and electronic component selection. To produce a high-quality board, careful material selection is vital. Specifications for the board’s processes and materials can be requested directly, while procurement of components can be guided by standards and price ranges. Additionally, critical components should be sourced from reputable commercial brands. Often, quotes for labor and materials exceed the expected budget of the contracting party, necessitating targeted communication between the R&D enterprise and the PCBA processing facility. High-quality components cannot be sourced at the price of inferior products. If cost control is necessary, collaboration with the processing plant’s purchasing staff is essential to explore ways to reduce expenses while maintaining product quality.

—

Let me know if you need further adjustments!