The Importance of Proper PCB Soldering

Soldering is a crucial process in electronics where two metals are joined using a filler metal. It is commonly used to connect electronic components to printed circuit boards (PCBs) to establish a reliable electrical connection.

Reasons for Proper Soldering

- Inadequate soldering can lead to short circuits, thermal damage, and signal interference.

Main PCB Soldering Technologies

The best way to ensure good solder joints is by using the correct tools and following proper soldering techniques. The most commonly used technologies include:

- Wave soldering

- Reflow soldering

- Selective soldering

Steps Involved in the PCB Soldering Process

- Clean the work area and gather necessary tools.

- Coat solder joints with a thin layer of solder.

- Preheat the PCB and soldering iron.

- Apply solder to the iron tip and contact the joint.

- Apply pressure and ensure a good connection.

- Check solder joints and clean the PCB.

Tools and Materials for PCB Soldering

- Soldering iron

- Solder wire

- Welding flux

Manual vs. Machine Soldering

PCB soldering can be done manually using a soldering iron or automatically using a machine. It is essential to follow proper temperature, use adequate solder wire, and adhere to component data manuals for quality soldering.

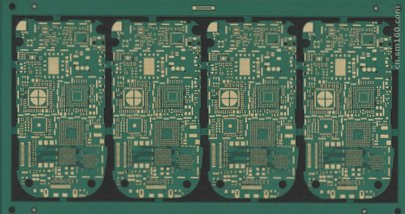

PCB Soldering: A Crucial Step in Electronic Manufacturing

When it comes to PCB soldering, the focus is on heating the soldering points to merge them with the copper foil on the circuit board. This fusion not only establishes electrical connections but also provides mechanical stability. In the realm of electronic equipment production, PCB soldering stands out as a fundamental procedure.