Choosing the Right PCBA Assembly Manufacturer

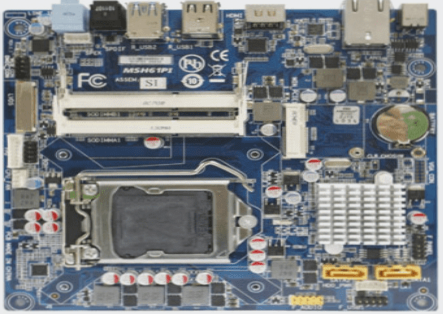

Machine Condition

When selecting a PCBA assembly manufacturer, it is crucial to consider the condition of their machines, particularly the pick-and-place and reflow ovens. The accuracy of the machines, whether old or new, and their data processing capabilities are essential factors to evaluate. Machines from Chinese or Japanese manufacturers can impact productivity and output. Precision is key, especially for handling the latest SMD layouts.

Older machines that are not well-maintained may result in production delays and reduced speed. Frequent breakdowns or inaccuracies in placement machines can slow down production significantly. Ensure the manufacturer’s machines can handle modern component packaging technologies to guarantee continuous PCB production.

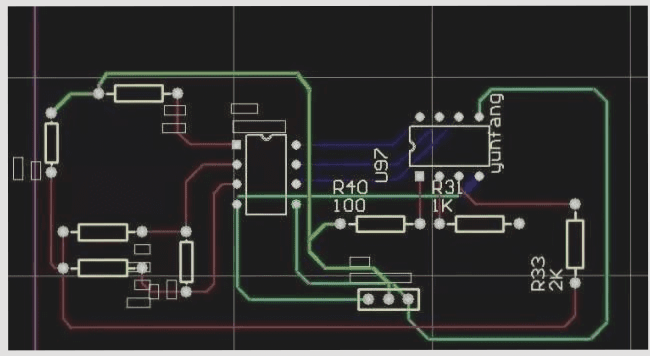

Quality Inspections

Quality control is paramount in Chinese production operations. When assessing PCB assembly services, it is essential to inquire about the quality inspections conducted by the manufacturer. Visual inspection, AOI vision machines, and functional testing are crucial processes that ensure the quality and reliability of the PCB components.

Production Lines

Consider the number of production lines a PCBA manufacturer operates. Multiple production lines allow for faster delivery of PCBA prototypes and efficient handling of orders. Manufacturers with the capability to run several production lines simultaneously offer a competitive advantage by expediting the production process.

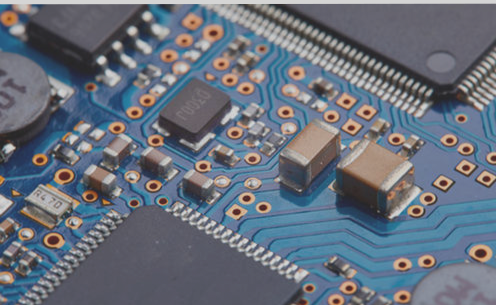

Standard Passive Component Inventory

Check if the manufacturer maintains a standard inventory of passive components like resistors, capacitors, and diodes. Having these common components in stock can streamline production and prevent delays. Ensure the manufacturer supports both small orders and mass production to maintain consistency throughout the product development and manufacturing phases.

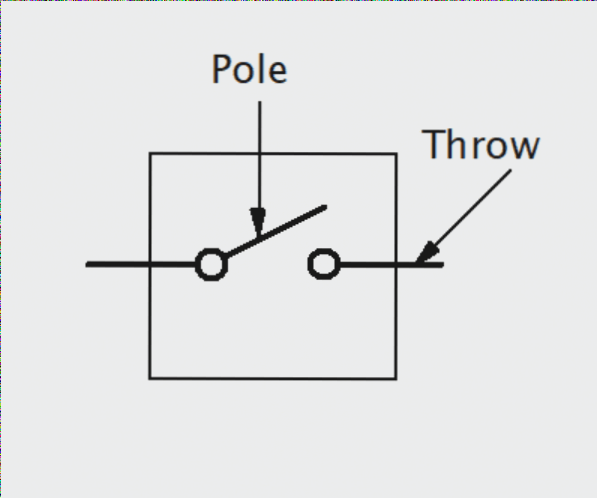

Solder Paste Application

Verify whether the manufacturer uses manual or automatic solder paste printers. Automatic solder paste printers are preferred for higher precision and efficiency, reducing the likelihood of human errors during the soldering process.

Worker Safety

It is crucial to ensure that workers in the manufacturing facility follow safety protocols to prevent accidents and maintain a healthy work environment.

Solving Common Challenges in PCB Assembly

Sometimes, a component may pose challenges for a placement machine, such as having a unique shape that the suction head cannot grasp or being incompatible with the board or tray. In such cases, manual placement by skilled operators is necessary, followed by reflow soldering to ensure secure connections.

Operators handling small parts must undergo proper training to work with precision. For tiny components, skills and tools like microscopes are essential to ensure accurate placement.

Ensuring Production Line Integrity

- Do they separate lead and lead-free production lines?

Suppliers using lead-based solder for cost reasons must prevent it from mixing with lead-free lines to avoid contamination. Physical barriers like walls or netted partitions are used to keep the production lines separated.

Quality Control and Efficiency

- What is their defect rate?

Understanding the number of defective PCBs per 100 units after rework is crucial for assessing production efficiency and delivery time. While many suppliers claim defect rates under 1%, actual performance may vary, impacting overall costs.

Proper Material Storage

- How do they store materials?

In humid and hot environments like China, components and PCBs are vacuum-sealed with silica gel packs upon storage to prevent moisture absorption and oxidation. This practice safeguards the components from damage over time.

If you have any PCB manufacturing requirements, feel free to contact me.