Choosing the Best PCBA Processing Supplier

Key Factors to Consider When Selecting a Reliable Supplier

- Complete Industry Qualifications

- Professional Engineering Procurement Team

- Top-Tier Production and Testing Equipment

- Comprehensive After-Sales Service System

When choosing a PCBA processing supplier, it is essential to look for industry certifications such as ISO9001, ISO13485 for medical electronics, and IATF16949 for automotive electronics. These certifications ensure that the supplier meets internationally recognized standards, guaranteeing the quality of the products produced.

A professional engineering and purchasing team is crucial for managing the production process efficiently. Experienced engineers play a vital role in ensuring the quality of products. Entrusting important projects to an inexperienced team can lead to disastrous results.

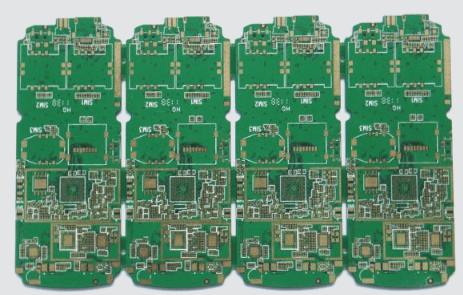

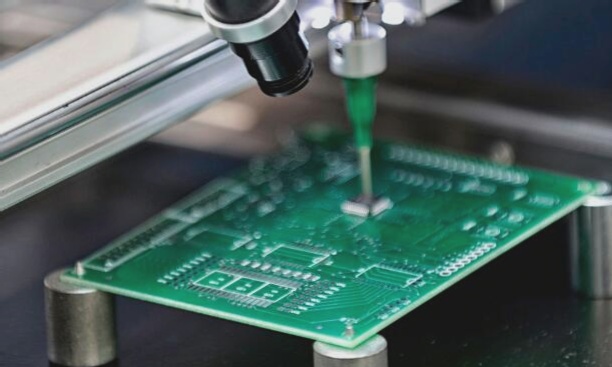

High-quality production and testing equipment are essential for maintaining product standards. Advanced technology is necessary to meet the increasing complexity and precision requirements of modern products and processes.

Choosing a supplier with a robust after-sales service system is crucial for long-term cooperation. Internal coordination and teamwork within the PCBA processing plant are key indicators of the level of collaboration and support you can expect. A reliable supplier will excel in delivery and after-sales service, ensuring a successful partnership.