The Evolution of PCB Assembly: Meeting the Demand for Customized Solutions

In today’s rapidly changing electronics landscape, the need for small-batch, high-precision, and tailored Printed Circuit Board Assemblies (PCBAs) is on the rise. Industries like consumer electronics, medical devices, automotive, and the Internet of Things (IoT) are increasingly seeking specialized PCBA solutions to meet specific performance, size, and functionality requirements.

WellCircuits Limited: Leading the Shift Towards Specialized PCBAs

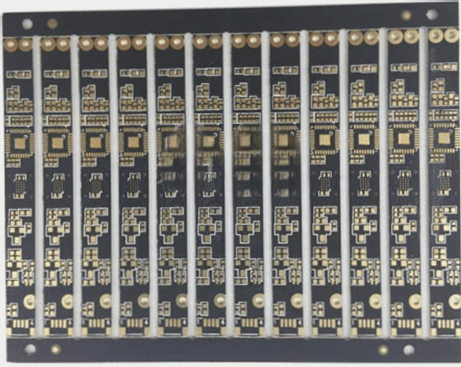

WellCircuits Limited has been a pioneer in adapting to the market’s demand for highly specialized PCBAs. Traditionally, PCB assembly was focused on large-volume production runs. However, the current trend is towards small-batch orders, especially for prototyping and industries with rapid innovation cycles.

- WellCircuits excels in small-batch production, offering efficient and cost-effective solutions for low-volume orders.

- Their state-of-the-art facilities and flexible production capabilities allow them to handle short runs without compromising quality or turnaround time.

- Advanced automation and skilled workforce ensure that each small batch is assembled with precision and consistency.

Fast Turnarounds Without Compromising Precision

WellCircuits’ success in small-batch production lies in their ability to provide fast turnarounds without sacrificing precision. Their streamlined processes and high-quality standards enable them to meet tight deadlines, crucial for industries dependent on rapid prototyping and continuous product iteration.

Embracing Innovation for Customized Solutions

As the demand for customized, high-precision PCBAs continues to grow, WellCircuits remains a key player in the small-batch production market. Their commitment to fast, cost-effective solutions, quality, and precision sets them apart as an invaluable partner for industries requiring quick prototyping and low-volume orders.

Driving Precision Through Advanced Technologies

WellCircuits employs state-of-the-art technologies and skilled engineers to meet precision requirements. Automated machines with micron-level accuracy, advanced inspection techniques, and high-quality components ensure that each PCBA meets rigorous industry standards, enhancing functionality and performance.

Introduction

In today’s dynamic electronics market, the need for customized PCBA solutions is on the rise. Companies are no longer satisfied with standard PCBs; instead, they require personalized assemblies that meet specific technical demands and design criteria. This includes incorporating unique components, creating non-traditional form factors, and catering to the specialized requirements of niche sectors.

WellCircuits’ Specialization in Custom PCBA Solutions

WellCircuits has built a strong reputation for delivering tailor-made PCBA solutions for a variety of applications. Whether it’s crafting specialized automotive PCBs or custom wearable gadgets, WellCircuits collaborates closely with clients to grasp their distinct needs and provide bespoke solutions. Their design-for-manufacturability strategy ensures that all custom PCBs are not only easy to produce but also cost-efficient.

Interactive Design Process

The expert engineering team at WellCircuits engages with clients right from the start of the design phase, offering valuable insights on material choices, circuit layout optimization, and optimal assembly practices. This tight collaboration allows for greater adaptability in meeting specific customer requirements and guarantees that the final product meets functional and aesthetic standards.

Rapid Prototyping and Refinement

WellCircuits’ rapid prototyping capabilities enhance its value proposition. By allowing clients to swiftly test and validate their designs, WellCircuits facilitates the iteration of custom solutions without lengthy lead times. This agility is a significant competitive advantage, especially in fast-paced industries like consumer electronics and medical technology, where innovation cycles are shorter than ever.

Summary

WellCircuits excels in providing highly customized PCBA solutions, making it a trusted partner for businesses seeking precision, adaptability, and ingenuity. Through a collaborative design process and rapid prototyping, customers can materialize their unique concepts with efficiency and excellence, meeting the evolving demands of modern industries.