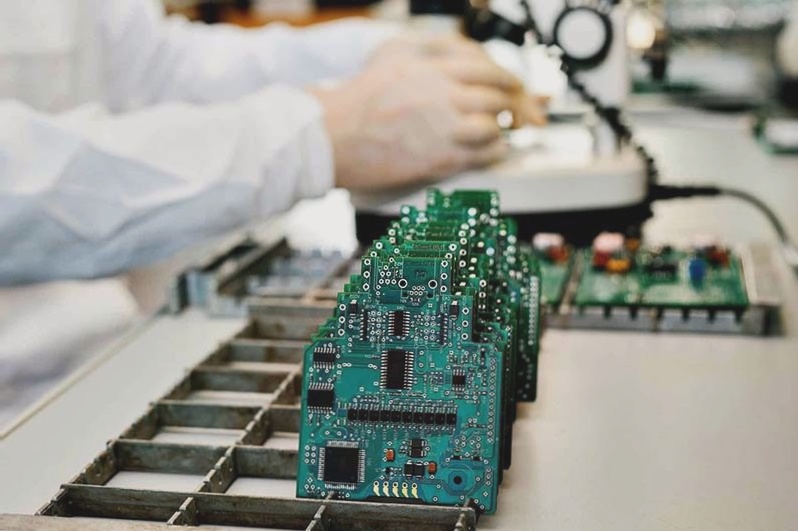

Navigating PCB Assembly Services: Balancing Quality and Cost

Engineers, especially beginners, often inquire about the “cheapest PCB assembly service” or ways to cut PCB assembly costs. While many PCB assemblers aim to lower costs, prioritizing price over quality can jeopardize project success. Striking a balance between assembly quality, customer service, and cost is paramount. Here are six tips to ensure high quality and lower PCB assembly costs:

1. Choose a Reliable and Professional PCB Component Manufacturer:

- Assess project requirements and budget before researching potential manufacturers.

- Examine certifications like ISO9001, RoHS, and UL to ensure manufacturing capability and adherence to regulations.

- Consider equipment, such as surface mount technology (SMT) mount equipment, for efficient and high-quality assembly.

- Evaluate component procurement services to streamline the process and save time and money.

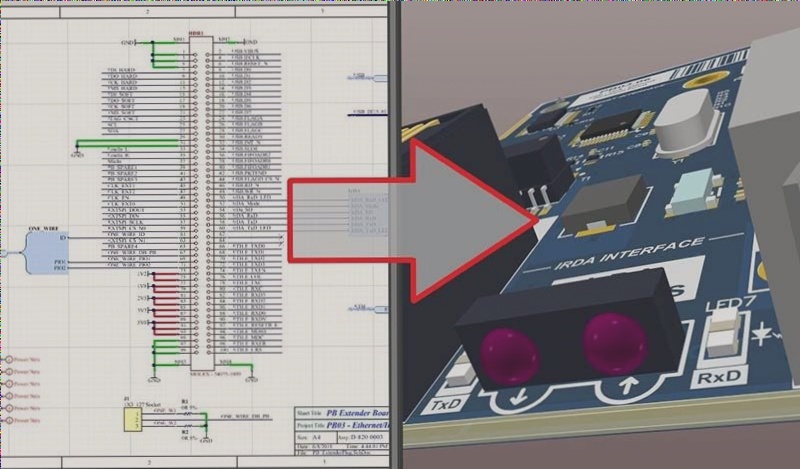

2. Optimize Bare PCB Design for Cost Efficiency:

- Conduct a Design for Manufacturing (DFM) check before actual manufacturing.

- Assess factors affecting the cost of bare PCBs, including layers, via technology, size, shape, and finish.

- Carefully arrange the number of holes to reduce PCB cost while maintaining functionality.

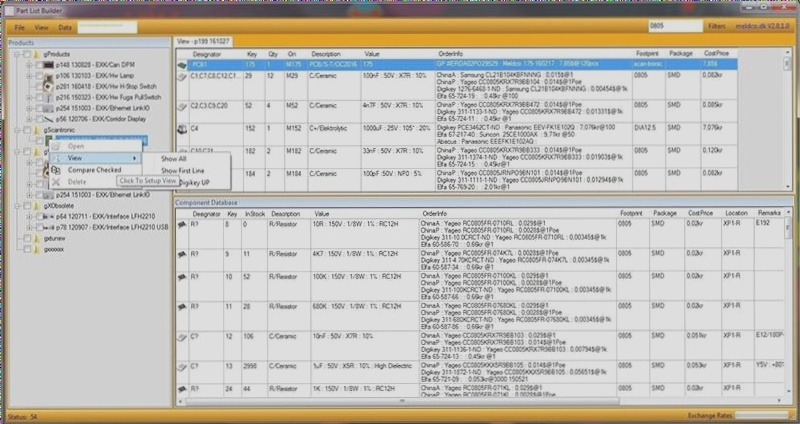

3. Prepare a Comprehensive Bill of Materials (BOM):

- Include essential BOM items, such as part number, manufacturer name, reference mark, quantity, description, case/package, SMT method, and more.

- Add replacement components to the BOM to account for component upgrades and replacements.

4. Clarify Component Procurement:

- Consider relying on PCB assembly manufacturers for component procurement.

- Evaluate relationships with franchised parts dealers for wholesale prices.

- Choose a manufacturer that aligns with your order size and can meet lead time requirements.

5. Adjust Order Volume and Delivery Time:

- Recognize the inverse relationship between order volume and cost per board component.

- Understand lead time calculations and consider longer lead times for lower prices.

6. Prioritize Inspection and Testing:

- Recognize the role of inspection or testing in ensuring high-quality products.

- Choose a PCB assembly manufacturer that offers inspection services and provides lower inspection costs.

- Set up PCB and PCBA labs for testing and quality assurance.

Conclusion: While cost reduction is a priority, compromising on quality can be detrimental. Adhering to these guidelines ensures a strategic approach to selecting a PCB component manufacturer, optimizing design, preparing a comprehensive BOM, clarifying procurement, adjusting order volume and lead time, and prioritizing inspection and testing. Long-term partnerships with reliable manufacturers foster smoother cooperation, mutual trust, and cost-cutting without sacrificing quality.