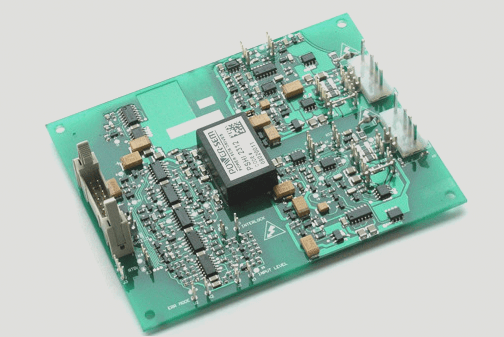

After passing through the automatic tin furnace, the insulation green paint on the circuit beneath the board can sometimes peel off. Ever wondered why that happens? What causes S/M peeling after chemical nickel gold?

There are three main possibilities for the green paint peeling off. The first possibility is that the green paint itself may not be durable enough to withstand the tin stove test. This could be due to expired or faulty paint, or poor application techniques leading to insufficient coating thickness. Most industry-standard green paints undergo rigorous heat resistance and reliability testing, so recurring issues are uncommon. In this scenario, it’s crucial to investigate whether there have been any changes in the paint material or application process.

The second possibility could be external factors such as flux supply or mechanical impacts, especially in high-temperature environments. Green paint tends to lose its hardness under such conditions, making it susceptible to scratches and peeling from external forces.

The third and most significant possibility is moisture absorption causing the green paint to burst before or during painting, or during storage. Water vapor expands drastically upon heating, leading to softening of the green paint and subsequent peeling. This issue can arise during various stages of circuit board production, including tin spraying, wave soldering, and assembly processes.

Regarding S/M peeling after chemical nickel gold, several factors could contribute. Firstly, improper copper processing could be a root cause. Secondly, applying S/M coatings before adequate drying may lead to issues. Thirdly, prolonged stagnation of the oxide layer can be problematic. Fourthly, using green paint unsuitable for gold ranges can cause problems. Fifthly, insufficient polymerization of the green paint may occur. Lastly, excessive high-temperature processes like gold plating or leaching can also lead to peeling. A thorough analysis is necessary to identify and address each potential cause.

In certain cases involving special green paints, the UV light reaction may be slow, requiring higher exposure energy and oxygen for optimal polymerization. If the polymerization degree is inadequate, subsequent baking won’t achieve the necessary strength. Operators should be informed of proper handling methods for such materials to avoid recurring issues.

These insights should provide a reference point for understanding and addressing paint peeling and related issues in PCB production.

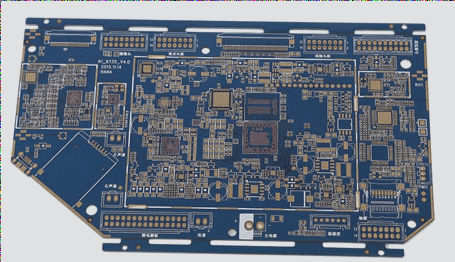

There are three main possibilities for the green paint peeling off. The first possibility is that the green paint itself may not be durable enough to withstand the tin stove test. This could be due to expired or faulty paint, or poor application techniques leading to insufficient coating thickness. Most industry-standard green paints undergo rigorous heat resistance and reliability testing, so recurring issues are uncommon. In this scenario, it’s crucial to investigate whether there have been any changes in the paint material or application process.

The second possibility could be external factors such as flux supply or mechanical impacts, especially in high-temperature environments. Green paint tends to lose its hardness under such conditions, making it susceptible to scratches and peeling from external forces.

The third and most significant possibility is moisture absorption causing the green paint to burst before or during painting, or during storage. Water vapor expands drastically upon heating, leading to softening of the green paint and subsequent peeling. This issue can arise during various stages of circuit board production, including tin spraying, wave soldering, and assembly processes.

Regarding S/M peeling after chemical nickel gold, several factors could contribute. Firstly, improper copper processing could be a root cause. Secondly, applying S/M coatings before adequate drying may lead to issues. Thirdly, prolonged stagnation of the oxide layer can be problematic. Fourthly, using green paint unsuitable for gold ranges can cause problems. Fifthly, insufficient polymerization of the green paint may occur. Lastly, excessive high-temperature processes like gold plating or leaching can also lead to peeling. A thorough analysis is necessary to identify and address each potential cause.

In certain cases involving special green paints, the UV light reaction may be slow, requiring higher exposure energy and oxygen for optimal polymerization. If the polymerization degree is inadequate, subsequent baking won’t achieve the necessary strength. Operators should be informed of proper handling methods for such materials to avoid recurring issues.

These insights should provide a reference point for understanding and addressing paint peeling and related issues in PCB production.