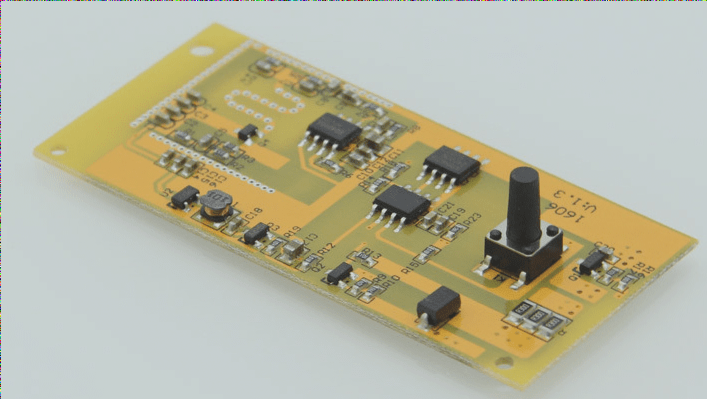

A few years ago, signal integrity discussions primarily focused on models and software. However, today, engineers are increasingly recognizing the influence of PCB materials on high-speed circuits.

As data rates rise, higher signal frequencies correspond to increased energy attenuation, as depicted below:

Simulation allows analysis of how different materials affect signals. For instance, varying dielectric loss angles (Df, representing different material types) yields diverse loss outcomes. Further analysis determines compliance with design requirements, illustrated below:

The diagram shows dielectric loss tangent (Df) ranging from 0.005 to 0.025. Higher Df values correlate with greater attenuation. Eye diagram analysis confirms that higher Df values result in narrower eye openings, as shown here:

Similar analysis applies to dielectric constant (Dk), primarily affecting impedance. Both Dk and Df vary with frequency, as seen in this material datasheet screenshot:

These parameters vary across frequencies in datasheets, typically offering limited data points. Using such data for simulations can lead to inaccuracies, as illustrated by significant disparities between manufacturer-provided raw data and specific material test results:

Material parameter testing and simulation yield curves like the one shown below, detailing dielectric constant decrease and dielectric loss tangent increase with frequency:

Using extracted material parameters for simulation of different transmission lines can closely align simulation results with test findings, as shown:

Both dielectric constant and dielectric loss tangent, as well as conductor roughness (typically copper), significantly impact signals.

If you have any questions about PCB or PCBA, please contact us at info@wellcircuits.com.