**Method 1: True Differential Test Method**

Step signal A and step signal B form a pair of differential step signals with opposite directions, equal amplitudes, and simultaneous emission.

Not only can we observe the differential step signal on the differential TDR device, but by monitoring the pair of step signals with a real-time oscilloscope, we can confirm that this is indeed a true differential signal. Since the TDR step pulse injected into the DUT (Device Under Test) is a differential signal, the TDR device can directly measure the characteristic impedance of the differential trace.

The primary advantage of using differential step signals for true differential TDR testing is that virtual grounding is possible.

Because the differential line and differential signal are balanced, the center voltage of the differential signal is at the same potential as the ground plane. Therefore, when using differential step signals for TDR testing, no separate grounding is required, as long as channels A and B are kept together. The DUT can be tested in this configuration.

**Method 2: “Superposition” Method (Pseudo-differential)**

In this method, step signal A and step signal B are not applied simultaneously, and their directions are not opposite, meaning the step signal injected into the DUT is not a true differential signal at all.

On the screen of this “pseudo-differential TDR” device, adjustments are typically made via manual software, meaning the step signal we observe is emitted simultaneously but in opposite directions. However, if we use a real-time oscilloscope to examine these two step pulses, we can observe the waveform shown in Figure 9. This allows us to see the real-time timing relationship between the two step pulses, which exhibit a time difference of 2 µs.

In other words, these two step signals are not true differential signals. Such a TDR step pulse is referred to as a pseudo-differential signal because it does not represent a genuine high-speed differential signal transmission process—instead, it involves equal amplitudes but opposite directions.

As a result, this method cannot directly measure the differential impedance of the DUT; instead, it can only simulate the differential impedance test through software calculations. On the TDR device, the calculated two amplitudes are equal, and the polarity of the opposite step pulse is generated. The limitation of this differential TDR test is that it cannot achieve simultaneous interaction between differential signals, nor can it achieve virtual grounding. Additionally, when performing a differential TDR test, the probes of Channel A and Channel B must have independent grounding points.

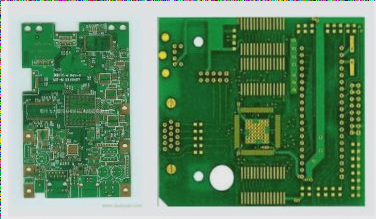

However, the connection points are typically not located near the actual differential lines within the PCB, making it impossible to measure the true differential traces inside the PCB. To overcome the limitation of “pseudo-differential” TDR equipment and to enable differential TDR measurement of actual PCB traces, most PCB manufacturers create a test strip with differential traces located around the PCB, known as a “coupon.” Figure 10 shows a typical PCB, with the test “coupon” at the top and the solid traces within the PCB at the bottom. To facilitate probe connection, the distance between the test points is generally large, up to 100 mil (2.54 mm), which is significantly greater than the spacing between differential lines.

At the same time, the connection location is next to the test point, with the same 100 mil spacing.

**2. Limitations and Differences of the “Coupon” Test**

There are key differences between the test “coupon” and the actual traces on the PCB:

1. Although the line spacing and width are the same, the test point spacing on the “coupon” is fixed at 100 mil (the initial value), which corresponds to the pin spacing of a dual-row in-line IC. This is different from the pin spacing at the ends of solid traces (such as chip pins) on the PCB. With the advent of QFP, PLCC, and BGA packages, the lead pitch of the chip is much smaller than the pitch of the dual in-line IC package (i.e., the pitch of the “coupon” test points).

2. The traces on the “coupon” are ideal straight lines, whereas the traces on the PCB are often curved or irregular due to design constraints. PCB designers and manufacturers can easily idealize the “coupon” traces, but the actual traces on the PCB are influenced by various factors that can cause them to be irregular.

3. The position of the solid traces within the “coupon” differs from the positions of the traces on the entire PCB. The “coupon” is located at the edge of the PCB and is typically removed by the manufacturer at the PCB factory. The actual trace positions within the circuit board vary; some traces are near the edge, while others are located centrally within the board.

Because of this third point, the “coupon” is not representative of the actual trace positions within the PCB. Additionally, modern PCBs are often designed with multiple layers of wiring, which is a factor that must be considered during production. When the PCB is laminated, pressure may not be uniform across different areas of the board, resulting in variations in the dielectric constant and, consequently, in the characteristic impedance. Thus, the TDR test on the “coupon” cannot fully reflect the true characteristic impedance of the actual traces on the PCB. Both PCB manufacturers and high-speed circuit designers ideally wish to perform direct TDR measurements on real high-speed differential circuits to obtain the most accurate characteristic impedance information.

The primary challenges in performing such direct tests are:

– The difficulty in locating a suitable ground point for a differential TDR probe.

– High-speed PCB designers typically do not design fixed-pitch ground points near the ends of traces (such as chip pins) when designing high-speed differential circuits.

**6. Advantages of TRUE Differential TDR Testing**

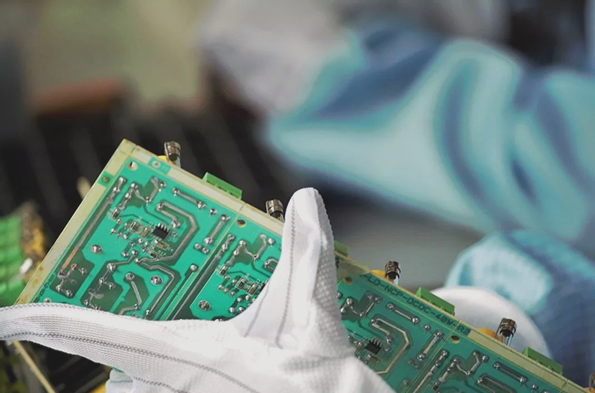

When discussing the differential TDR test method, it is important to note that if the step signal sent by the TDR device is a true differential signal, virtual grounding can be achieved. In other words, the differential TDR probe does not need to be grounded to the PCB under test.

As long as the tester has access to a differential TDR probe with adjustable spacing, the test can be performed effectively. Figure 11 shows a differential TDR probe with an 18 GHz bandwidth, designed for differential TDR testing. The probe spacing is continuously adjustable between 0.5 mm and 4.5 mm, allowing for easy testing of test points as small as the tip of a ballpoint pen, all while being manageable with just one hand. Thanks to the high bandwidth of the probe, excellent test resolution can be achieved.

Figure 12 shows the results of testing the differential line “coupon.” The red waveform represents the initial test results of the “coupon,” followed by a small strip on the line (shown within the red circle), and subsequent testing produces the white waveform. The small impedance discontinuity caused by the sticker is clearly visible, thanks to the high-bandwidth differential TDR probe.

The true differential TDR device, equipped with a high-bandwidth differential probe, allows for accurate PCB differential impedance testing without needing to find a specific connection point on the PCB. By simply adjusting the probe to the appropriate spacing, real differential traces within the PCB can be easily detected.