PCB Impedance Control: A Comprehensive Guide

Evolution of PCB Manufacturing and Design

In recent years, PCB manufacturing and design have evolved significantly. What once started as basic board designs has transformed with technological advancements. Today, new performance criteria have been introduced, leading to increased complexity in design and manufacturing practices.

Understanding Impedance in PCBs

Impedance, measured in ohms, represents the resistance to energy flow in a circuit or transmission line. It combines circuit resistance and reactance, where reactance arises from inductance and capacitance effects. While DC circuits are primarily resistance-driven, high-frequency circuits are heavily influenced by reactance and impedance.

The Importance of Controlled Impedance

Maintaining impedance consistency within a system is crucial to prevent failures and performance issues. Controlled impedance, a fundamental design concept, ensures impedance mismatches are kept within acceptable limits. For instance, in coaxial cable design, precise control over insulator properties and component proportions is essential to regulate cable impedance.

LDI’s Role in PCB Manufacturing

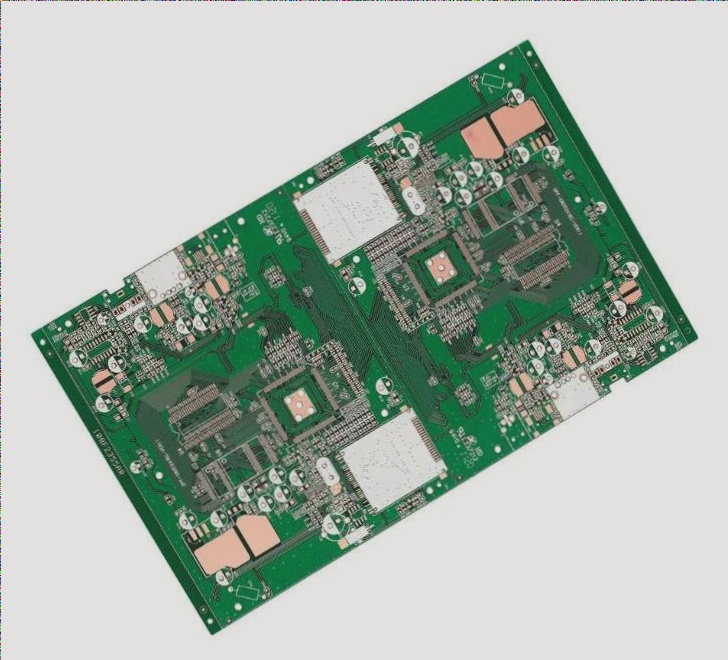

In PCB fabrication, traces act as conductors, laminates serve as insulators, and planes function as shields. The impedance of a printed circuit board depends on the materials and dimensions used during manufacturing.

Enhancing Signal Transmission with Impedance Control

Efficient signal transmission within a PCB requires matching source and load impedances. Failure to do so leads to signal reflections, affecting quality. With the rise of high-speed signal technologies, PCB designs incorporating controlled impedance have become increasingly important.

Implementing Impedance Control in PCB Production

Controlling impedance in PCB fabrication involves meticulous stacking and trace design. By adjusting trace dimensions such as width and spacing, impedance values can be modified to meet specific requirements.

Considering the Impact of Permittivity

Impedance in PCBs is also influenced by permittivity, which measures a material’s ability to store electrical energy within an electric field.