PCB Localization and MRI Technology in Medical Diagnostics

Imported Equipment Maintenance and Localization Efforts

- Since 1983, over 77.5 billion worth of PCB technologies and equipment have been imported, leading to a peak maintenance period. Experts emphasize the need to prioritize localization to reduce costs and promote active development.

Magnetic Resonance Imaging (MRI) Technology

MRI technology plays a vital role in early tumor detection and soft tissue lesion diagnosis. There are two main types: superconducting MRI and permanent magnet MRI, each with unique methods of forming the primary imaging magnetic field.

Challenges and Solutions in MRI Equipment Localization

- Superconducting MRI systems offer high magnetic field strength but come with exorbitant manufacturing and operational costs. To address this, leveraging PCB reverse engineering is crucial for effective localization and maintenance.

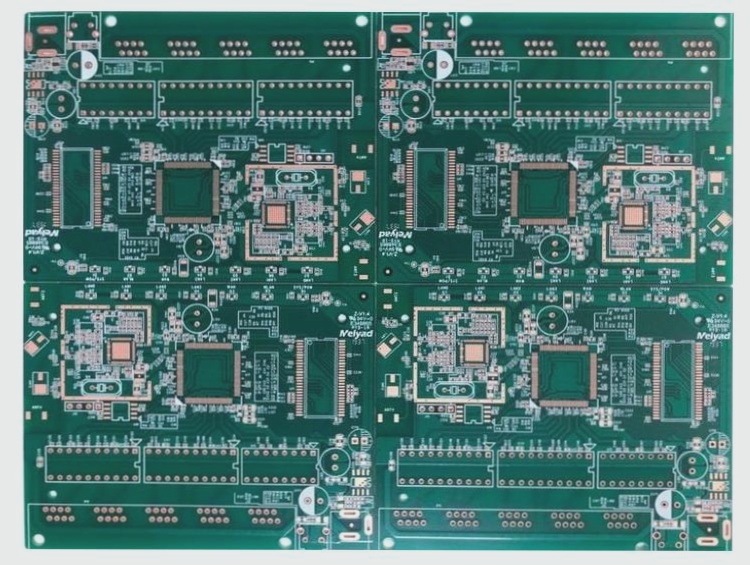

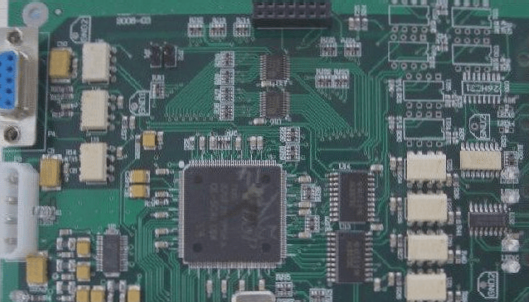

- PCB reverse engineering involves acquiring advanced electronic circuit designs from abroad to develop superior domestic products. This method extracts technical data for rapid prototyping and competitive benchmarking, fostering innovation.

- Localization and maintenance of imported MRI equipment present challenges for hospitals. PCB modification offers a scientifically grounded strategy to expedite localization, reduce costs, and enhance equipment sustainability.