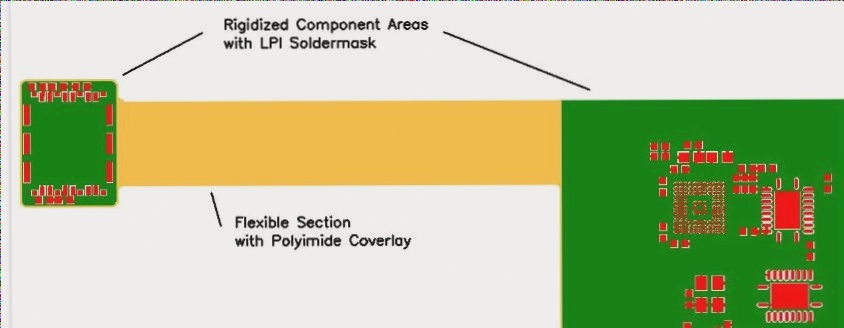

(7) Reliable structure, mature and advanced technology.

In circuit and structural design, the number of connectors and metallized holes should be minimized. Circuit components and chips should be soldered directly on the printed board as much as possible. Surface mount devices should be selected and surface mount technology should be used to avoid poor contact to ensure the reliability of the equipment.

(8) Thermal design.

Excessive temperature is one of the important factors that reduce the performance and reliability of the equipment. For this reason, thermal protection measures should be taken to control and reduce the temperature rise of the equipment during operation, ensure good heat dissipation, and improve the thermal reliability of the equipment. Additionally, too low temperature will also reduce equipment performance and reliability, and some components cannot work normally when the ambient temperature is too low. Therefore, the equipment used in low-temperature environments should also be tested under those conditions. The temperature conditions and environment in which the equipment operates must be considered in the design.

(9) Electromagnetic compatibility design.

When the equipment is working, it will be interfered with by many electromagnetic fields, both natural and man-made. This is especially true for military equipment. In modern high-tech electronic warfare, a very important technical means is to emit high-energy electromagnetic waves locally to destroy the components in the opponent’s equipment, thereby causing the equipment to fail. Therefore, effective anti-interference measures such as shielding and filtering should be taken to prevent the interference of noise and interfering electromagnetic fields on the equipment and ensure the reliable operation of the equipment.

(10) Anti-vibration shock design.

Equipment will be affected by various vibrations and impacts during use and transportation, which will affect its reliability. For this reason, the mechanical strength and rigidity of the equipment should be improved, and vibration damping and buffering measures should be taken to strengthen the equipment against vibration and impact to improve equipment reliability.

(11) Use a fault indicating device.

Design a fault detection circuit and a fault alarm device to find faults in time, thereby shortening the troubleshooting time of the equipment.

(12) Simple operation and convenient maintenance.

The function of operation and maintenance in the equipment is one of the main factors to ensure the reliability of the equipment. In the design, plug-in units and modules should be used as much as possible, and at the same time, modularization, standardized structure, and quick disassembly structure should be adopted to facilitate operation and maintenance. Facts have proven that the modular structure of the equipment can greatly simplify operation and facilitate maintenance.

In circuit and structural design, the number of connectors and metallized holes should be minimized. Circuit components and chips should be soldered directly on the printed board as much as possible. Surface mount devices should be selected and surface mount technology should be used to avoid poor contact to ensure the reliability of the equipment.

(8) Thermal design.

Excessive temperature is one of the important factors that reduce the performance and reliability of the equipment. For this reason, thermal protection measures should be taken to control and reduce the temperature rise of the equipment during operation, ensure good heat dissipation, and improve the thermal reliability of the equipment. Additionally, too low temperature will also reduce equipment performance and reliability, and some components cannot work normally when the ambient temperature is too low. Therefore, the equipment used in low-temperature environments should also be tested under those conditions. The temperature conditions and environment in which the equipment operates must be considered in the design.

(9) Electromagnetic compatibility design.

When the equipment is working, it will be interfered with by many electromagnetic fields, both natural and man-made. This is especially true for military equipment. In modern high-tech electronic warfare, a very important technical means is to emit high-energy electromagnetic waves locally to destroy the components in the opponent’s equipment, thereby causing the equipment to fail. Therefore, effective anti-interference measures such as shielding and filtering should be taken to prevent the interference of noise and interfering electromagnetic fields on the equipment and ensure the reliable operation of the equipment.

(10) Anti-vibration shock design.

Equipment will be affected by various vibrations and impacts during use and transportation, which will affect its reliability. For this reason, the mechanical strength and rigidity of the equipment should be improved, and vibration damping and buffering measures should be taken to strengthen the equipment against vibration and impact to improve equipment reliability.

(11) Use a fault indicating device.

Design a fault detection circuit and a fault alarm device to find faults in time, thereby shortening the troubleshooting time of the equipment.

(12) Simple operation and convenient maintenance.

The function of operation and maintenance in the equipment is one of the main factors to ensure the reliability of the equipment. In the design, plug-in units and modules should be used as much as possible, and at the same time, modularization, standardized structure, and quick disassembly structure should be adopted to facilitate operation and maintenance. Facts have proven that the modular structure of the equipment can greatly simplify operation and facilitate maintenance.