In-Circuit Test (ICT) for PCB Assembly (PCBA)

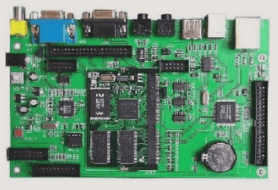

In-Circuit Test (ICT) is a crucial electrical testing method used to verify circuit connections on PCB Assemblies (PCBAs) and ensure they meet specified requirements. This test is conducted in the final production phase to validate quality and reliability.

Key Steps in ICT:

- Prepare Test Fixtures: Create fixtures to secure and make contact with the PCBA.

- Connect Test Instruments: Link fixtures to ICT equipment like probes and power supplies.

- Define Test Points: Identify circuit connection points for testing voltage, current, and signals.

- Perform Tests: Place PCBA on fixture, use probes to test resistance, capacitance, and more.

- Analyze Results: Review test data to ensure PCBA meets electrical requirements.

- Record and Save: Maintain test records for analysis and traceability.

Importance of ICT Testing:

Conducting ICT tests helps identify manufacturing issues promptly, ensuring correct circuit connections and meeting electrical standards. This process enhances PCBA quality, reduces defects, and improves overall production efficiency in the electronics manufacturing sector.