The Importance of Choosing the Right PLC Industrial Control Board

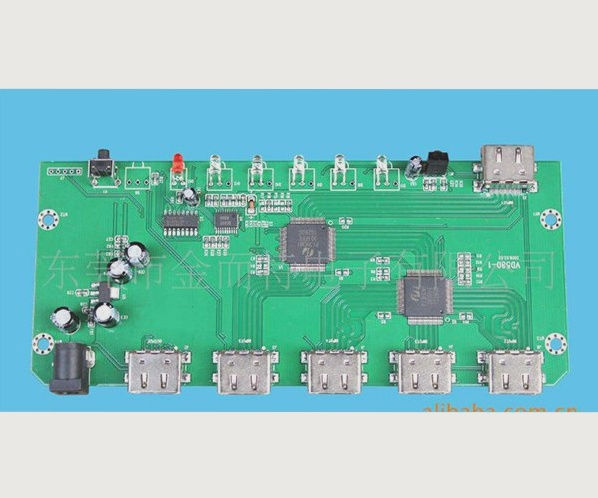

- When evaluating a PLC industrial control board, consider the chipset, planning and layout, and materials used.

- Manufacturers follow chipset design guidelines to create high-quality industrial computer motherboards.

- Differences in design approaches between manufacturers in Europe, America, and Taiwan impact cost control and innovation.

- Effective layout planning is crucial to ensure stability, functionality, and cost efficiency.

- Proper positioning of interface components and logical arrangement of CPU and chipsets are key considerations.

- Attention to details like capacitor proximity to the CPU interface is essential for optimal performance.

To select the right PLC industrial control board, understanding the chipset, layout planning, and material choices is essential. Manufacturers’ design approaches and adherence to guidelines greatly impact the quality and functionality of industrial computer motherboards. Proper layout planning, interface component positioning, and logical arrangement of critical components are vital for stability and performance. Paying attention to these details ensures the optimal functioning of industrial control boards.

Choose Wisely for Optimal Performance

Industrial Computer Motherboard PCB Design and Wiring Planning

Key Concepts for Industrial Computer Motherboard Design

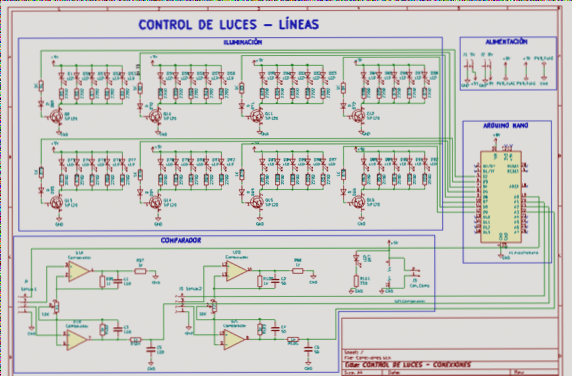

- The importance of equal-length clock lines in the layout

- Utilizing a 45-degree rotation for efficient organization

When designing an industrial computer motherboard, the distance between the north bridge chip and the CPU and memory is critical. Known as “equal-length clock lines,” this concept ensures smooth communication between components. Some manufacturers employ a clever 45-degree rotation technique to optimize the layout, reducing wiring length and maintaining equal-length clock lines.

Specialized Wiring Planning Techniques

- Understanding circuit characteristics for tailored planning

- The significance of serpentine wiring

Wiring planning for industrial computer motherboards requires specialized knowledge due to unique circuit characteristics. Contrary to popular belief, the number of serpentine lines does not necessarily indicate superior planning. Serpentine wiring is crucial for maintaining equal line lengths and minimizing electromagnetic interference. By utilizing zigzag routing and snake-shaped wiring, signal integrity and EMI concerns can be addressed effectively.

Optimal wiring density is essential to prevent layout inconsistencies and ensure system stability. When selecting a PLC industrial control board, consider these wiring principles to enhance the performance and reliability of your industrial computer motherboard.