Printed Circuit Board Industry Trends and Characteristic Impedance Control

Our country’s economy is thriving with a focus on economic construction, reform, and opening up. The electronic industry is experiencing rapid growth, with the printed circuit board (PCB) sector following suit. As the world undergoes technological and industrial changes, PCBs play a crucial role in the development of electronics, especially with the increasing demands for miniaturization, digitization, high frequency, and multi-functional electronic devices.

For PCBs used in high-frequency and high-speed digital signal transmission, ensuring circuit continuity, absence of short circuits, and meeting characteristic impedance requirements are essential for optimal performance.

Importance of Characteristic Impedance in PCBs

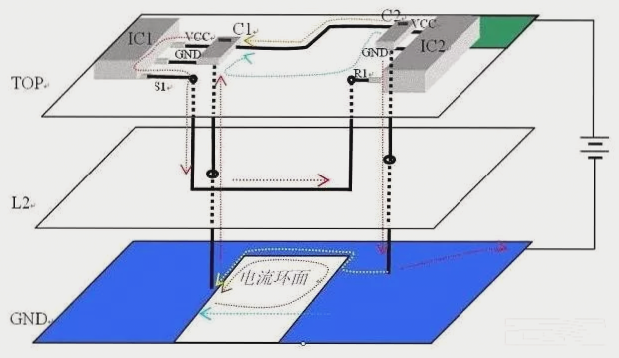

Characteristics impedance control in PCBs is vital for preventing signal reflections, maintaining signal integrity, reducing transmission loss, and facilitating impedance matching. This is particularly crucial in surface microstrip structure multilayer boards.

Surface Microstrip Line and Characteristic Impedance

The surface microstrip line, known for its relatively high characteristic impedance, is commonly used in PCB designs. It consists of a signal line surface separated from a reference plane by insulating materials.

- Microstrip Z Formula: Z = (87 / √(Er+1.41)) (ln[5.98H / (0.8W+T)])

- Stripline Z Formula: Z = (60 / √Er) (ln[4H / (0.67π(0.8W+T)])

Factors such as dielectric constant (Er), dielectric thickness (H), wire width (W), and wire copper thickness (T) significantly impact characteristic impedance. Proper substrate material selection is crucial in PCB design to ensure optimal characteristic impedance performance.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย