The Influence of Dielectric Constant on Material Performance

The dielectric constant of a material, determined by the manufacturer at 1 MHz frequency, varies among materials due to resin content differences. This study focuses on epoxy glass cloth to explore the relationship between dielectric constant and frequency changes. As frequency rises, the dielectric constant decreases. It is crucial for the material’s dielectric constant to match the operating frequency in practical applications. Using the average value is usually sufficient. Higher dielectric constant leads to slower signal transmission within the material. To achieve fast signal transmission, reducing the dielectric constant while maintaining high characteristic resistance is essential. Choosing a material with a low dielectric constant is key for selecting a high characteristic resistance value.

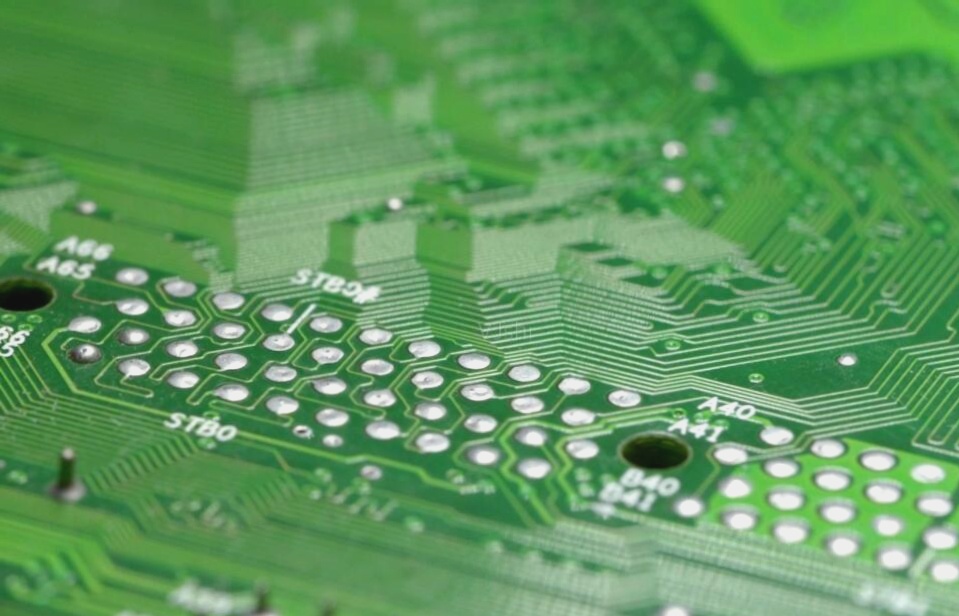

Impact of Wire Width and Thickness on Impedance

Wire width plays a significant role in varying characteristic impedance. Taking the surface microstrip line as an example, the correlation between impedance and wire width is explained. A small 0.025mm change in wire width results in a 5-6 ohms impedance shift, as shown in the figure. In production, when using 18μm copper foil to control signal line surface impedance, the acceptable wire width variation is ±0.015mm. However, with a 35μm copper foil, the tolerance for wire width variation extends to 0.025mm. This highlights the substantial impedance change due to allowable wire width adjustments during production. Designers must carefully determine wire width to meet design requirements for wire capacity, temperature, and impedance value. Manufacturers need to ensure that the line width meets design specifications during production, adjusting it within the tolerance range to meet impedance standards.

Wire thickness is determined by the conductor’s current-carrying capacity and allowable temperature rise. The plating layer thickness, typically around 25μm, adds to the wire thickness, which includes the copper foil thickness and plating layer thickness. Before electroplating, it is crucial to clean the wire surface thoroughly, removing any residues or oil black marks to prevent issues like un-plated copper, which can alter local wire thickness and impact impedance values. Care must also be taken during brushing to avoid changes in wire thickness and subsequent impedance shifts.