Selection of Etching Solution for Printed Circuit Boards (PCBs)

The choice of etching solution plays a critical role in the production of high-quality printed circuit boards (PCBs), especially for precise and dense circuit patterns. Several factors influence the characteristics of the etchant, including:

- Physical and Chemical Aspects:

-

- The concentration of the etching solution: Determined based on metal corrosion principles and copper foil structure.

- The composition of the etching solution: Different chemical compositions affect etching rates. For example, acid cupric chloride has a different etching coefficient compared to alkaline cupric chloride.

- Temperature: Proper temperature control accelerates etching while excessively high temperatures can harm the equipment.

- Thickness of copper foil: Thinner foils require shorter etching times, while thicker foils may lead to excessive side etching.

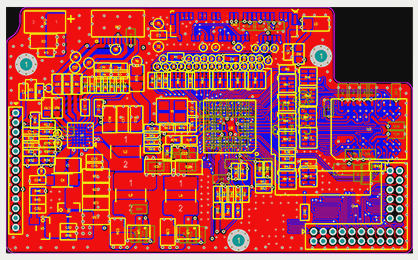

- Circuit geometry: Balanced circuit pattern distribution is crucial for uniform etching solution flow.

- Mechanical Aspects:

-

- Type of equipment: Horizontal mechanical transmission etching equipment with swing nozzle devices is preferred for high-precision PCBs.

- Spray technology: Chain and cone spray systems promote even etching, while arc swing spray mode is ideal for thin wire production.

- Distance and pressure: Optimal settings between the nozzle and substrate surface are essential for uniform etching.

- Fluid Mechanics:

-

- Surface tension: Affects etching rate by influencing solid surface wetting.

- Viscosity: Impacts solution flow on PCB surfaces and requires proper maintenance for ideal results.