PCBA Processing: Ensuring Quality Through First Article Inspection

PCBA processing has evolved over time due to advancements in technology and equipment, leading to the implementation of crucial steps like first article inspection. This initial test plays a pivotal role in identifying and rectifying issues early in the production process to prevent defects and ensure product quality.

Understanding First Article Inspection

- First article inspection involves thorough examination and testing of the initial product to confirm quality standards.

- The primary goal is to detect any potential issues that could impact product quality, preventing batch defects and scrappage.

Key Points for First Article Inspection in PCBA Processing

- The initial piece includes the first board and panel, essential for SMT modeling and functional testing.

- Production shifts require the first panel to maintain quality and prevent errors from carrying over.

- ECN changes and process modifications necessitate re-inspection to ensure quality standards are met.

Considerations for First Inspection

- Implement protective measures like electrostatic protection and verify information accuracy.

- Ensure component positioning, polarity, and soldering quality align with technical requirements.

- Inspect incoming components for color, size, and polarity to meet quality standards.

Interlocking Inspection Mechanism in SMT Chip Processing

- Self-inspection: Engineers check component orientation and placement accuracy.

- Mutual inspection: Operators verify materials and notify engineers of any issues.

- Full inspection: Quality inspectors conduct comprehensive checks using tools like multimeters and X-ray for BGA devices to ensure compliance with customer standards.

Three-Inspection System Foundation

The foundation of the three-inspection system lies in the initial piece, which acts as the benchmark for comparing samples and agreed-upon guidance documents between the factory and the customer. Sample accuracy covers material correctness and welding quality. Customer guidance documents take precedence for consistency; in their absence, the sample takes priority. This principle safeguards both the foundry and the customer, ensuring product quality and averting quality losses stemming from errors on either side.

Insights from PCBA Processing Workshop

Extensive experience in PCBA processing affirms that the first inspection system is instrumental in early issue detection, preventing the scrapping of entire batches. This initial inspection uncovers systemic issues like fixture wear, positioning errors, inaccuracies in measuring instruments, misinterpretation of drawings, or formula errors, enabling prompt corrective actions. Its core objective is to reveal systemic factors influencing product quality in PCBA processing and manufacturing, thereby thwarting the production of non-compliant batches.

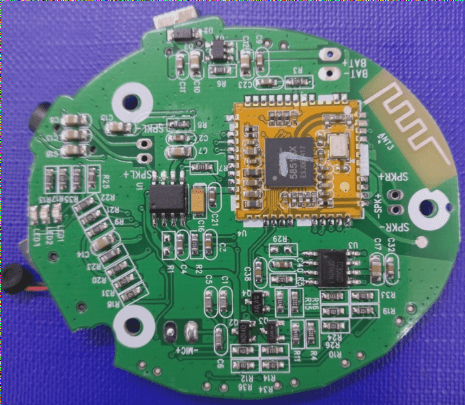

Exploring PCBA Board

The aforementioned elucidates the primary process of the first inspection in PCBA processing.