Surface Pre-Treatment

The copper sheet, post-cutting, often retains oxides, grease, and other contaminants on its surface, necessitating initial pretreatment. The primary objectives of this process include impurity removal and enhancing the surface roughness of the copper foil. These steps ensure robust adhesion between the dry film and the surface, preventing issues like film stripping, short circuits, or insufficient diffusion coating. The composition of the copper layer surface varies with different pretreatment methods, each tailored to specific process requirements. Typical methods include abrasive blasting, chemical treatment, and mechanical grinding.

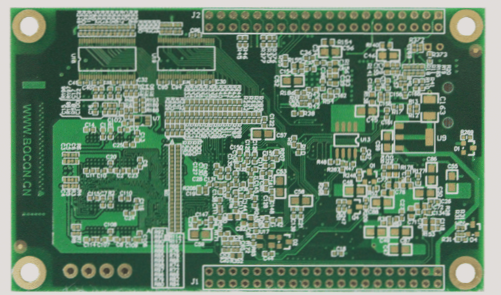

The production of inner layer circuits follows a principle of image transfer, where photographic materials transfer designed circuit patterns onto required copper surfaces. This process involves six primary steps.

Dry Film Lamination

Lamination applies a special photographic film onto the treated copper surface. Dry and wet films, both photosensitive, undergo polymerization under UV light, forming a stable substance that prevents plating and etching during subsequent processes. The choice between dry and wet film depends on operational environment and needs. Here, we focus on the use of dry film.

During lamination, the polyethylene protective film is removed, and photoresist is applied to the copper clad laminate under heated, pressurized conditions. Heating softens the resist layer, enhancing its fluidity under pressure from hot-press rollers and binders, completing the lamination process. Key factors during lamination include pressure, temperature, and transfer speed, conducted in a dust-free, yellow-light environment due to the film’s UV sensitivity.

Exposure

Each PCB layer requires a corresponding film image. Precise alignment of film with dry film-laminated substrate precedes exposure. UV light induces photopolymerization in light-transmitting parts of the film, creating a cured, insoluble macromolecular structure that remains after washing out unreacted areas in the developer. Exposure machine settings, exposure duration, and dry film quality influence image exposure quality.

Developing

Using developer solution, technicians wash away unpolymerized dry film, leaving behind a protective layer on the board surface for etching.

Etching

Exposed inner layer panels proceed to the etching area, where developer-removed dry film exposes copper surfaces. Copper chloride etches exposed areas, forming desired circuit traces.

Stripping

In this step, sodium hydroxide solution removes exposed dry film protecting copper surfaces. Operators ensure no residues remain that could affect copper conductivity. Once stripping is complete, the PCB circuit is fully formed, proceeding to automated optical inspection for consistency checks between etched patterns and design.

Inner Layer AOI Inspection

This stage is critical as inner layer errors are irreversible post-lamination. Automated optical inspection compares scanned etched pattern images with original Gerber file designs, detecting defects like open circuits, shorts, nicks, or copper residues. Technicians assess detected issues for correctability; failing that, panels may be scrapped. Passing AOI, inner layers proceed to lamination.

If you have any questions about PCB or PCBA, please contact us at info@wellcircuits.com.