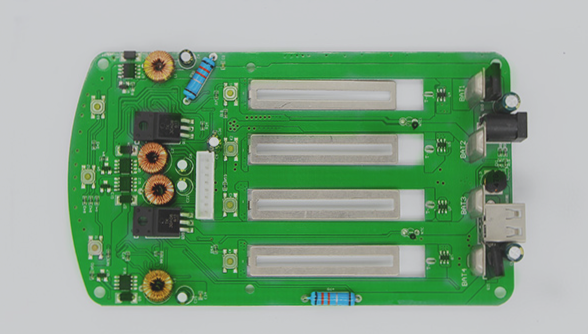

I recently made a board that has a lot of components on it, many of which seem to be spec’d to reflow at different temperatures. For example, there is an OEM XTend radio module that suggests a temperature profile that maxes out at 250C.

I set the oven’s temperature profile to the suggested profile for the radio, but when the board came out the plastic connector had turned brown and had obviously gotten too hot. My question is; is the proper way to address this to do multiple passes at different temperatures to avoid damaging components? Or should I stick to hand-soldering these plastic connectors?