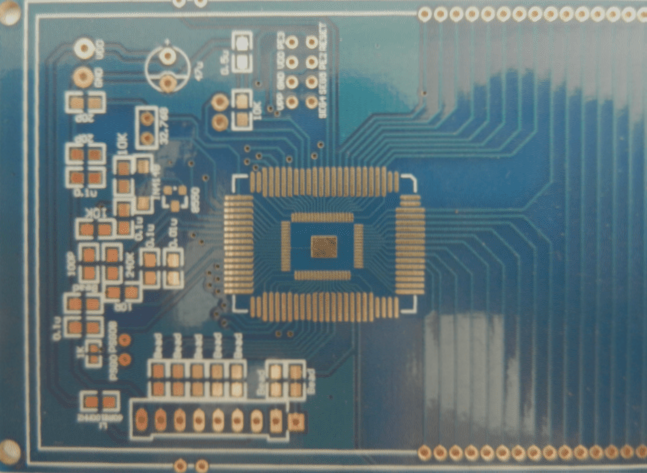

1. When manual welding, it is important to develop good habits. First, visually inspect the PCB board before welding and use a multimeter to check for short circuits in key circuits, especially the power supply and ground. Avoid randomly throwing the soldering iron during soldering, as solder on the chip’s solder feet, especially on surface mount components, can be difficult to identify.

2. Refer to the PCB diagram on the computer to identify the short-circuited network and determine the closest connection point. Pay close attention to any short circuits within the IC.

3. When a short circuit is identified, carefully cut the line on a separate board, especially effective for single or double-layer boards. After cutting the line, power up each functional block separately and remove any affected components.

4. Utilize short circuit location analyzers, such as the Singapore PROTEQ CB2000 short circuit tracker, Hong Kong Lingzhi Technology QT50 short circuit tracker, or British POLAR ToneOhm950 multi-layer board short circuit detector.

5. For BGA chips on multi-layer boards (more than 4 layers), separate the power supply for each chip during design. Use magnetic beads or 0-ohm resistors for connections to easily detect and locate short circuits between power supply and ground. Carefully solder BGA chips by machine to avoid inadvertently short-circuiting adjacent power supply and ground solder balls.

6. Exercise caution when soldering small surface mount capacitors, particularly power filter capacitors (103 or 104), which can easily cause short circuits between power supply and ground. Testing capacitors before soldering can help prevent potential issues caused by short circuits due to faulty components.

2. Refer to the PCB diagram on the computer to identify the short-circuited network and determine the closest connection point. Pay close attention to any short circuits within the IC.

3. When a short circuit is identified, carefully cut the line on a separate board, especially effective for single or double-layer boards. After cutting the line, power up each functional block separately and remove any affected components.

4. Utilize short circuit location analyzers, such as the Singapore PROTEQ CB2000 short circuit tracker, Hong Kong Lingzhi Technology QT50 short circuit tracker, or British POLAR ToneOhm950 multi-layer board short circuit detector.

5. For BGA chips on multi-layer boards (more than 4 layers), separate the power supply for each chip during design. Use magnetic beads or 0-ohm resistors for connections to easily detect and locate short circuits between power supply and ground. Carefully solder BGA chips by machine to avoid inadvertently short-circuiting adjacent power supply and ground solder balls.

6. Exercise caution when soldering small surface mount capacitors, particularly power filter capacitors (103 or 104), which can easily cause short circuits between power supply and ground. Testing capacitors before soldering can help prevent potential issues caused by short circuits due to faulty components.