When I first delved into electronics and circuit design, seasoned engineers often emphasized the importance of being adept technicians alongside being skilled engineers. Merely grasping the performance objectives of a board and devising circuit layouts to meet those objectives isn’t sufficient. It’s equally crucial to comprehend the structural intricacies of boards and the rationale behind them. I’ve found this assertion to hold true, as neglecting these aspects during the design phase can lead to myriad issues during manufacturing.

Among the foremost challenges confronting PCBs during both manufacture and operation is heat. Ironically, heat plays a pivotal role in the manufacturing process, particularly during assembly when components are soldered onto boards. In practice, reflow furnaces are employed for surface-mount technology, subjecting the board to prolonged heating.

Assessing the board’s thermal endurance entails understanding how heat propagates and how thermal diffusivities vary across the board. This parameter hinges on the board’s material, thickness, and is typically determined through laser flash analysis (LFA). Once the thermal diffusivity is clearly defined, let’s delve into the process of conducting LFA for a PCB, paving the way for integrating thermal management into the design process.

Understanding PCBA Thermal Diffusivity

Thermal management often takes a back seat unless dealing with high-power PCBs where effective heat dissipation is paramount. While critical, this is just one facet of adept thermal management. To gain a more holistic perspective, let’s delineate some key terms.

PCB Thermal Management Terminology:

Heat dissipation involves expelling surplus heat from the circuit board. Various technologies accomplish this, including radiators for high-power components and strategically positioned heat sinks. Heat dissipation poses the primary challenge during operation.

During PCB assembly, the board’s temperature needs to be elevated, especially with the use of lead-free solder, which may require temperatures around 250°C (482°F). Unlike during PCB operation, where rapid heat removal is sought, achieving uniform heat distribution during manufacturing is imperative for high-quality solder joints.

Heat naturally flows from regions of higher temperature to lower temperature unless artificially coerced or pumped. Thermal diffusivity denotes the rate of this transfer across a circuit board.

From these definitions, it’s evident that thermal diffusivity is pivotal for dissipation during operation and distribution during manufacturing. Let’s now explore how to ascertain this parameter for manufacturing through laser flash analysis.

Laser Flash Analysis for PCB Fabrication

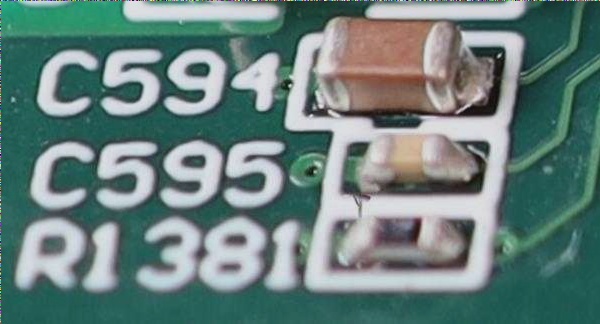

In the figure above, an example of the device used to perform Laser Flash Analysis (LFA) is depicted. The figure illustrates plates utilized in the test setup. Typically, the test is conducted within an enclosed apparatus, with subsequent analysis carried out using software.

The parameter of primary concern in this context is thermal diffusivity, which can be determined utilizing the following formula:

(1) α= K/(⍴c p)

Where:

α represents thermal diffusivity,

K denotes thermal conductivity,

⍴ signifies material density, and

cp stands for specific heat capacity.

Each variable in the equation is intimately linked with temperature, enabling the detection of variations as temperature fluctuates. Armed with this data, precise thermal analysis for your design can be achieved, thereby facilitating effective thermal management strategies.

Laser Flash Analysis and its Role in PCBA Manufacturing

The outcomes of LFA hold significant value in ensuring that the chosen board materials and PCB layouts are optimized for your manufacturing process. Moreover, Cadence’s CELSIUS Thermal Solver can be harnessed to formulate a comprehensive thermal management strategy, inclusive of electrothermal co-simulation.

Among the foremost challenges confronting PCBs during both manufacture and operation is heat. Ironically, heat plays a pivotal role in the manufacturing process, particularly during assembly when components are soldered onto boards. In practice, reflow furnaces are employed for surface-mount technology, subjecting the board to prolonged heating.

Assessing the board’s thermal endurance entails understanding how heat propagates and how thermal diffusivities vary across the board. This parameter hinges on the board’s material, thickness, and is typically determined through laser flash analysis (LFA). Once the thermal diffusivity is clearly defined, let’s delve into the process of conducting LFA for a PCB, paving the way for integrating thermal management into the design process.

Understanding PCBA Thermal Diffusivity

Thermal management often takes a back seat unless dealing with high-power PCBs where effective heat dissipation is paramount. While critical, this is just one facet of adept thermal management. To gain a more holistic perspective, let’s delineate some key terms.

PCB Thermal Management Terminology:

Heat dissipation involves expelling surplus heat from the circuit board. Various technologies accomplish this, including radiators for high-power components and strategically positioned heat sinks. Heat dissipation poses the primary challenge during operation.

During PCB assembly, the board’s temperature needs to be elevated, especially with the use of lead-free solder, which may require temperatures around 250°C (482°F). Unlike during PCB operation, where rapid heat removal is sought, achieving uniform heat distribution during manufacturing is imperative for high-quality solder joints.

Heat naturally flows from regions of higher temperature to lower temperature unless artificially coerced or pumped. Thermal diffusivity denotes the rate of this transfer across a circuit board.

From these definitions, it’s evident that thermal diffusivity is pivotal for dissipation during operation and distribution during manufacturing. Let’s now explore how to ascertain this parameter for manufacturing through laser flash analysis.

Laser Flash Analysis for PCB Fabrication

In the figure above, an example of the device used to perform Laser Flash Analysis (LFA) is depicted. The figure illustrates plates utilized in the test setup. Typically, the test is conducted within an enclosed apparatus, with subsequent analysis carried out using software.

The parameter of primary concern in this context is thermal diffusivity, which can be determined utilizing the following formula:

(1) α= K/(⍴c p)

Where:

α represents thermal diffusivity,

K denotes thermal conductivity,

⍴ signifies material density, and

cp stands for specific heat capacity.

Each variable in the equation is intimately linked with temperature, enabling the detection of variations as temperature fluctuates. Armed with this data, precise thermal analysis for your design can be achieved, thereby facilitating effective thermal management strategies.

Laser Flash Analysis and its Role in PCBA Manufacturing

The outcomes of LFA hold significant value in ensuring that the chosen board materials and PCB layouts are optimized for your manufacturing process. Moreover, Cadence’s CELSIUS Thermal Solver can be harnessed to formulate a comprehensive thermal management strategy, inclusive of electrothermal co-simulation.

1. As shown above, the Celsius temperature allows you to assess the heat distribution of the board and can be combined with electrical analysis to plan your cooling strategy.