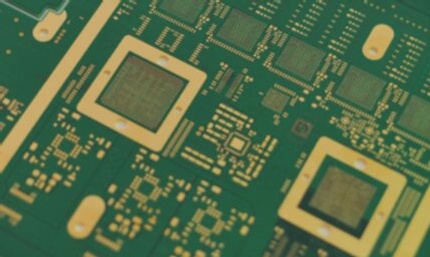

1. Introduction to Black FR4 PCB Insulation Board

2. The black FR4 PCB insulation board, also known as fiberglass board, is commonly used as a soft base and is then wrapped with cloth and leather to create beautiful wall and ceiling decorations. This versatile material is widely used and is known for its sound absorption, sound insulation, heat insulation, environmental friendliness, and flame retardant properties. The black FR4 PCB insulation board is also referred to as fiberglass board, glass fiber board, FR4 PCB reinforcing plate, FR-4 epoxy resin board, flame retardant insulating board, epoxy board, FR4 PCB light board, epoxy glass cloth board, and drill base plate for circuit board.

Black fr4 PCB Insulation Board

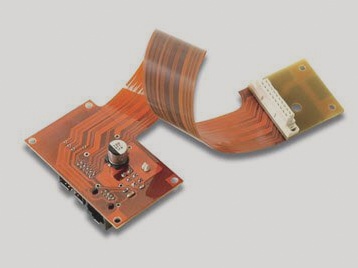

1. Black fr4 PCB insulation board, also known as glass fiber insulation board or glass fiber composite board, is composed of glass fiber material and high heat resistance composite material. It does not contain asbestos and is harmless to the human body. It has high mechanical and dielectric properties, good heat and moisture resistance, and excellent processability. It is widely used for plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCB.ICT fixtures, and table grinding pads.

2. Injection molding typically requires high-temperature materials and low-temperature molds. When using the same machine, thermal insulation is necessary to keep the injection molding temperature low and prevent the injection molding machine temperature from becoming too high. This can be achieved by installing an insulation board between the injection mold and the injection machine. This helps shorten the production cycle, improve productivity, reduce energy consumption, and enhance the quality of finished products. Continuous production processes ensure product quality stability, prevent machine overheating, electrical failure, and oil leakage in the hydraulic system.

1. Features of Black fr4 PCB Insulation Board

The main technical characteristics and applications of black fr4 PCB insulation board include stable electrical insulation performance, good flatness, smooth surface without pits, and thickness tolerance that exceeds the standard. It is suitable for products with high-performance electronic insulation requirements, such as FPC reinforcing plates, high-temperature resistant plates for tin furnaces, carbon diaphragms, precision planetary wheels, PCB test frames, electrical equipment insulation partitions, insulation pads, transformer insulation, motor insulation, deflection coil terminal boards, and electronic switch insulation boards. It is also widely used in wall and ceiling decoration due to its sound absorption, sound insulation, heat insulation, environmental protection, and flame retardant properties.

2. Black fr4 PCB Epoxy Resin

Black fr4 PCB epoxy resin refers to organic polymer compounds with two or more epoxy groups in the molecule. Its molecular structure is characterized by the presence of active epoxy groups in the molecular chain, allowing it to react with various curing agents to form insoluble and insoluble polymers with a three-dimensional network structure.

Characteristics

– Can meet various application requirements

– Strong adhesion to various substances

– Low shrinkage during curing

– Excellent mechanical properties

– Excellent electrical properties

– Chemical stability

– Special chemical stability with proper selection of epoxy resin and curing agent for black fr4 PCB applications.

2. The black FR4 PCB insulation board, also known as fiberglass board, is commonly used as a soft base and is then wrapped with cloth and leather to create beautiful wall and ceiling decorations. This versatile material is widely used and is known for its sound absorption, sound insulation, heat insulation, environmental friendliness, and flame retardant properties. The black FR4 PCB insulation board is also referred to as fiberglass board, glass fiber board, FR4 PCB reinforcing plate, FR-4 epoxy resin board, flame retardant insulating board, epoxy board, FR4 PCB light board, epoxy glass cloth board, and drill base plate for circuit board.

Black fr4 PCB Insulation Board

1. Black fr4 PCB insulation board, also known as glass fiber insulation board or glass fiber composite board, is composed of glass fiber material and high heat resistance composite material. It does not contain asbestos and is harmless to the human body. It has high mechanical and dielectric properties, good heat and moisture resistance, and excellent processability. It is widely used for plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCB.ICT fixtures, and table grinding pads.

2. Injection molding typically requires high-temperature materials and low-temperature molds. When using the same machine, thermal insulation is necessary to keep the injection molding temperature low and prevent the injection molding machine temperature from becoming too high. This can be achieved by installing an insulation board between the injection mold and the injection machine. This helps shorten the production cycle, improve productivity, reduce energy consumption, and enhance the quality of finished products. Continuous production processes ensure product quality stability, prevent machine overheating, electrical failure, and oil leakage in the hydraulic system.

1. Features of Black fr4 PCB Insulation Board

The main technical characteristics and applications of black fr4 PCB insulation board include stable electrical insulation performance, good flatness, smooth surface without pits, and thickness tolerance that exceeds the standard. It is suitable for products with high-performance electronic insulation requirements, such as FPC reinforcing plates, high-temperature resistant plates for tin furnaces, carbon diaphragms, precision planetary wheels, PCB test frames, electrical equipment insulation partitions, insulation pads, transformer insulation, motor insulation, deflection coil terminal boards, and electronic switch insulation boards. It is also widely used in wall and ceiling decoration due to its sound absorption, sound insulation, heat insulation, environmental protection, and flame retardant properties.

2. Black fr4 PCB Epoxy Resin

Black fr4 PCB epoxy resin refers to organic polymer compounds with two or more epoxy groups in the molecule. Its molecular structure is characterized by the presence of active epoxy groups in the molecular chain, allowing it to react with various curing agents to form insoluble and insoluble polymers with a three-dimensional network structure.

Characteristics

– Can meet various application requirements

– Strong adhesion to various substances

– Low shrinkage during curing

– Excellent mechanical properties

– Excellent electrical properties

– Chemical stability

– Special chemical stability with proper selection of epoxy resin and curing agent for black fr4 PCB applications.