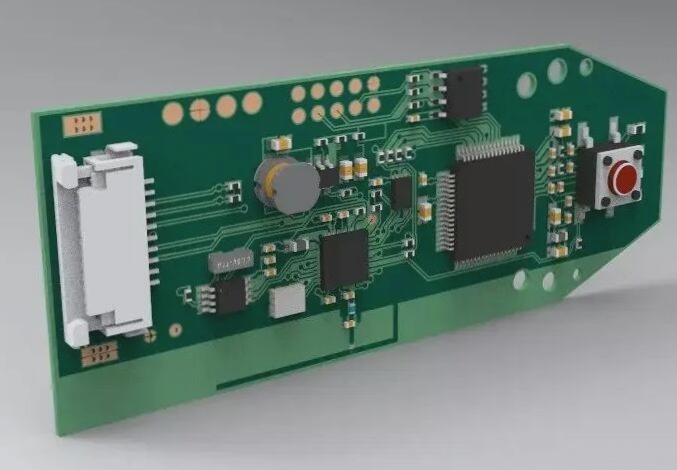

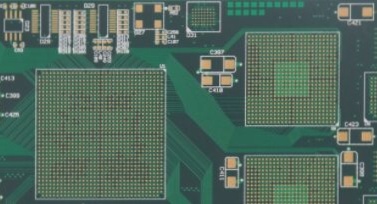

1. When it comes to designing printed circuit board components (PCBA), different test procedures can be implemented with few or no errors. By executing the test program, you can get rid of all the minor errors and thus improve the PCBA and overall product quality. Therefore, PCBA testing can help you reduce your manufacturing costs. Several different test programs can be used for this purpose. Some of these include manufacturing defect analyzers, in-circuit, boundary scanning, and functional testing. Among these methods, online and functional testing procedures are widely used. Which method is better than the others? To find out, read the following article.

2. What is an online test? What’s good about it? On-line testing (ICT) involves measuring and testing all components on a PCB. This process helps identify defective components and can be replaced accordingly. Here are some of the key advantages of ICT:

3. This test program helps identify PCB manufacturing defects, such as open connections, welding short circuits, and faulty or missing components.

4. Programming an online tester is very easy. It can be done by fetching a file from a PCB layout.

5. The ICT process takes very little time to perform a full inspection of the circuit, during which time it helps to detect all power and ground short circuits.

6. Power-on testing is an ICT that almost eliminates the need for customer debugging.

7. On-line testing enables multiple tests to be performed without a power supply to the device under test (DUT). This helps perform security testing and protects the component from any potential damage.

8. The ICT test platform can be used in both Windows and UNIX operating systems, making it universal.

9. What is functional testing? What’s good about it? Functional testing (FCT) is the process of checking the function and electrical properties of a PCB. This is usually the last step of testing before the PCB component is delivered to the customer. In this type of testing, you test the functionality of the entire PCB component rather than individual components. Some of the main benefits of functional testing are as follows:

10. Each type of test has its advantages and disadvantages. Therefore, it is difficult to say which type is superior to the others. It all depends on the application.

2. What is an online test? What’s good about it? On-line testing (ICT) involves measuring and testing all components on a PCB. This process helps identify defective components and can be replaced accordingly. Here are some of the key advantages of ICT:

3. This test program helps identify PCB manufacturing defects, such as open connections, welding short circuits, and faulty or missing components.

4. Programming an online tester is very easy. It can be done by fetching a file from a PCB layout.

5. The ICT process takes very little time to perform a full inspection of the circuit, during which time it helps to detect all power and ground short circuits.

6. Power-on testing is an ICT that almost eliminates the need for customer debugging.

7. On-line testing enables multiple tests to be performed without a power supply to the device under test (DUT). This helps perform security testing and protects the component from any potential damage.

8. The ICT test platform can be used in both Windows and UNIX operating systems, making it universal.

9. What is functional testing? What’s good about it? Functional testing (FCT) is the process of checking the function and electrical properties of a PCB. This is usually the last step of testing before the PCB component is delivered to the customer. In this type of testing, you test the functionality of the entire PCB component rather than individual components. Some of the main benefits of functional testing are as follows:

10. Each type of test has its advantages and disadvantages. Therefore, it is difficult to say which type is superior to the others. It all depends on the application.