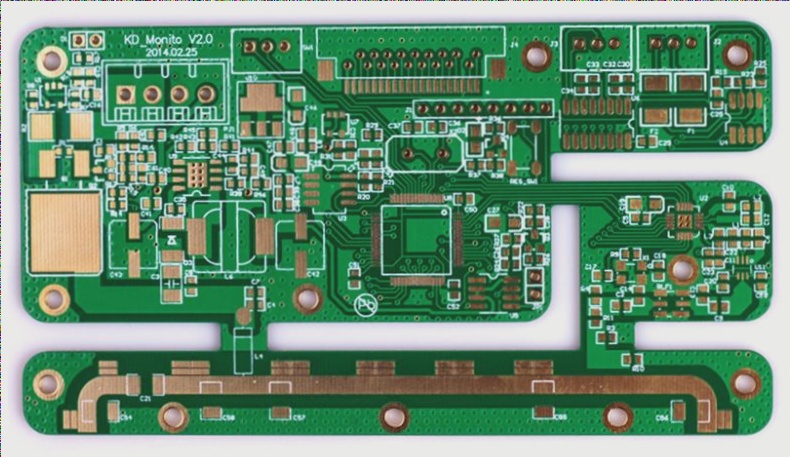

1 PCB, also known as a printed circuit board, is a crucial component in the electronic industry.

2 Nearly every electronic device, from digital watches and calculators to computers, communication electronics, and military weapon systems, relies on printed boards to electrically interconnect electronic components like integrated circuits.

PCB Manufacture

The printed circuit board (PCB) is composed of an insulating base plate, connecting wires, and a solder pad for assembling and welding electronic components. It has the dual function of conducting wires and insulating base plates. PCBs can replace complex wiring and achieve electrical connections between various components in the circuit, simplifying the assembly and welding work of electronic products and reducing the workload of traditional wiring methods. Moreover, they greatly reduce the labor intensity of workers. Additionally, PCBs reduce the overall volume, product costs, and improve the quality and reliability of electronic equipment.

PCBs have good product consistency and can adopt standardized designs, which is conducive to achieving mechanization and automation in the production process. Furthermore, the entire assembled and debugged printed circuit board can serve as an independent spare part, facilitating the exchange and maintenance of the entire product. At present, printed circuit boards have been widely used in the production and manufacturing of electronic products.

PCB Characteristics

The reason why PCBs have been increasingly widely used is that they have many unique advantages, which are roughly as follows:

1. High-density: PCBs have been able to develop high density with the improvement of integrated circuit integration and the advancement of installation technology.

2. High reliability: Through a series of inspections, testing, and aging tests, it is possible to ensure that PCBs can work reliably for a long time (with a lifespan of usually 20 years).

3. Designability: The requirements for various properties of PCBs (electrical, physical, chemical, mechanical, etc.) can be achieved through design standardization and standardization, which leads to short design time and high efficiency.

4. Producibility: PCBs adopt modern management, which can achieve standardization, scale (quantity), and automated production, ensuring the consistency of product quality.

5. Testability: We have established relatively complete testing methods and standards, which can be used to detect and evaluate the qualification and service life of PCB products through various testing equipment and instruments.

6. Assemblability: PCB products are convenient for the standardized assembly of various components and for automated and large-scale mass production. In addition, assembling a PCB as a whole with various other components can form larger components, systems, and even the entire machine.

7. Maintainability: Due to the standardized design and large-scale production of components in PCB products, these components are also standardized. Once the system malfunctions, it can be quickly, conveniently, and flexibly replaced to quickly restore the system’s operation.

PCBs also have other advantages, such as miniaturization, lightweight, and high-speed signal transmission.

Functions of PCBs in Electronic Devices

1. Provide mechanical support for fixing and assembling various electronic components such as integrated circuits, achieve wiring and electrical connections or insulation between various electronic components such as integrated circuits, and provide the required electrical characteristics.

2. Provide solder mask graphics for automatic welding, and identification characters and graphics for component insertion, inspection, and maintenance.

3. Avoid manual wiring errors in electronic equipment, ensure the quality of electronic products, improve labor productivity, reduce costs, and facilitate maintenance.

4. Provide the required electrical characteristics, characteristic impedance, and electromagnetic compatibility characteristics for the circuit in the high-speed or high-frequency circuit.

5. Provide certain electrical functions and improve product reliability in PCBs with embedded passive components.

6. Provide an effective chip carrier for miniaturized chip packaging of electronic components in large-scale and ultra-large-scale electronic packaging components.

PCB Design Principles

When determining the position of special components and laying out all components of a circuit based on its functional units, the following principles should be followed:

1. Consider the PCB size, the position of special components, and the layout of all components of the circuit according to its functional units. Ensure a proper PCB size, position special components based on principles, and layout components based on functional units.

2. Follow specific principles for positioning and layout:

a. Shorten wiring between high-frequency components as much as possible and reduce their distribution parameters and electromagnetic interference.

b. Avoid components susceptible to interference being too close to each other and keep input and output components as far away as possible.

c. Increase the distance between components or wires with a high potential difference to avoid short circuits caused by discharge.

d. Consider the layout of adjustable components based on the structural requirements of the whole machine.

3. Arrange circuit components to ensure signal flow, minimize and shorten leads and connections, arrange components in parallel, and consider mechanical strength for larger circuit boards.

PCB circuit boards are important sub-components of electronic devices and are crucial for proper assembly and connectivity in electronic products. Their business coverage is very extensive, as they form the foundation of the electronic products industry chain.

2 Nearly every electronic device, from digital watches and calculators to computers, communication electronics, and military weapon systems, relies on printed boards to electrically interconnect electronic components like integrated circuits.

PCB Manufacture

The printed circuit board (PCB) is composed of an insulating base plate, connecting wires, and a solder pad for assembling and welding electronic components. It has the dual function of conducting wires and insulating base plates. PCBs can replace complex wiring and achieve electrical connections between various components in the circuit, simplifying the assembly and welding work of electronic products and reducing the workload of traditional wiring methods. Moreover, they greatly reduce the labor intensity of workers. Additionally, PCBs reduce the overall volume, product costs, and improve the quality and reliability of electronic equipment.

PCBs have good product consistency and can adopt standardized designs, which is conducive to achieving mechanization and automation in the production process. Furthermore, the entire assembled and debugged printed circuit board can serve as an independent spare part, facilitating the exchange and maintenance of the entire product. At present, printed circuit boards have been widely used in the production and manufacturing of electronic products.

PCB Characteristics

The reason why PCBs have been increasingly widely used is that they have many unique advantages, which are roughly as follows:

1. High-density: PCBs have been able to develop high density with the improvement of integrated circuit integration and the advancement of installation technology.

2. High reliability: Through a series of inspections, testing, and aging tests, it is possible to ensure that PCBs can work reliably for a long time (with a lifespan of usually 20 years).

3. Designability: The requirements for various properties of PCBs (electrical, physical, chemical, mechanical, etc.) can be achieved through design standardization and standardization, which leads to short design time and high efficiency.

4. Producibility: PCBs adopt modern management, which can achieve standardization, scale (quantity), and automated production, ensuring the consistency of product quality.

5. Testability: We have established relatively complete testing methods and standards, which can be used to detect and evaluate the qualification and service life of PCB products through various testing equipment and instruments.

6. Assemblability: PCB products are convenient for the standardized assembly of various components and for automated and large-scale mass production. In addition, assembling a PCB as a whole with various other components can form larger components, systems, and even the entire machine.

7. Maintainability: Due to the standardized design and large-scale production of components in PCB products, these components are also standardized. Once the system malfunctions, it can be quickly, conveniently, and flexibly replaced to quickly restore the system’s operation.

PCBs also have other advantages, such as miniaturization, lightweight, and high-speed signal transmission.

Functions of PCBs in Electronic Devices

1. Provide mechanical support for fixing and assembling various electronic components such as integrated circuits, achieve wiring and electrical connections or insulation between various electronic components such as integrated circuits, and provide the required electrical characteristics.

2. Provide solder mask graphics for automatic welding, and identification characters and graphics for component insertion, inspection, and maintenance.

3. Avoid manual wiring errors in electronic equipment, ensure the quality of electronic products, improve labor productivity, reduce costs, and facilitate maintenance.

4. Provide the required electrical characteristics, characteristic impedance, and electromagnetic compatibility characteristics for the circuit in the high-speed or high-frequency circuit.

5. Provide certain electrical functions and improve product reliability in PCBs with embedded passive components.

6. Provide an effective chip carrier for miniaturized chip packaging of electronic components in large-scale and ultra-large-scale electronic packaging components.

PCB Design Principles

When determining the position of special components and laying out all components of a circuit based on its functional units, the following principles should be followed:

1. Consider the PCB size, the position of special components, and the layout of all components of the circuit according to its functional units. Ensure a proper PCB size, position special components based on principles, and layout components based on functional units.

2. Follow specific principles for positioning and layout:

a. Shorten wiring between high-frequency components as much as possible and reduce their distribution parameters and electromagnetic interference.

b. Avoid components susceptible to interference being too close to each other and keep input and output components as far away as possible.

c. Increase the distance between components or wires with a high potential difference to avoid short circuits caused by discharge.

d. Consider the layout of adjustable components based on the structural requirements of the whole machine.

3. Arrange circuit components to ensure signal flow, minimize and shorten leads and connections, arrange components in parallel, and consider mechanical strength for larger circuit boards.

PCB circuit boards are important sub-components of electronic devices and are crucial for proper assembly and connectivity in electronic products. Their business coverage is very extensive, as they form the foundation of the electronic products industry chain.